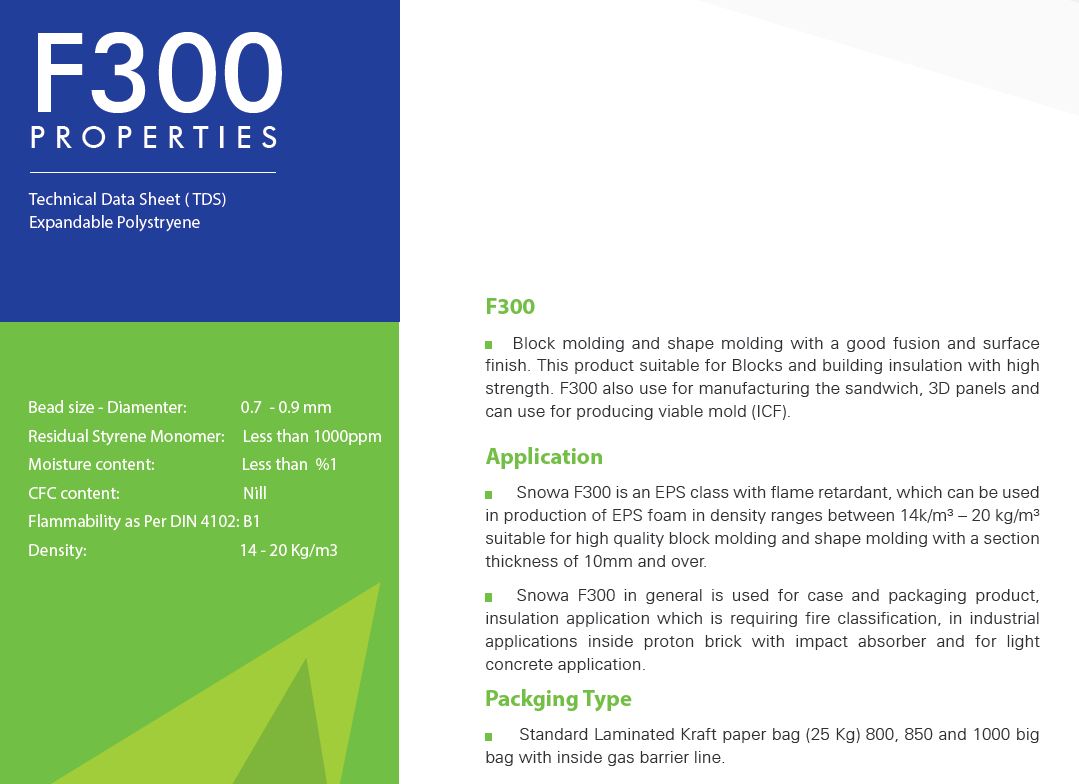

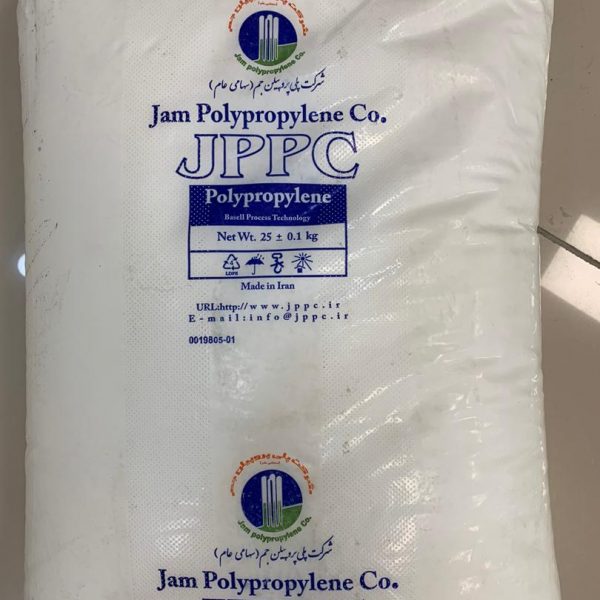

Packging Type:

Standard Laminated Kraft paper bag (25 Kg) 800, 850 and 1000 big

bag with inside gas barrier line.

Storage:

Snowa F300 should be stored in well-ventilated storage areas with

a temperatures preferably not exceeding 25°C. It should be protected

against unsuitable weather conditions and direct sun light. Partially used

bag should be closed as tight as original conditions, and should be

consumed in a short time. In order to maintain the expansion potential

it is recommended to use within three months after production, if the

package is not opened.

Processing Conditions:

All Processing conditions might be changeable according to a kind of

equipment’s and an aging time of materials.

From expansion of the beads to block or mod shaped products, the

entire process is managed with steam.

Snowa F300 is expandable in a single expansion at densities between

14 Kg/m³ – 20 Kg /m³. The minimum density achievable may vary

depending on the expander type and process conditions.

As temporary storage time in silos recommended 5-24 hour depend

on the density, atmosphere and process conditions.

For special applications please contact our technical service.

Caution:

Snowa F300 requires to be avoided restrictively from sparks and

flames, in order to prevent against static electricity, the equipment and

machine must be provided by enough Earth connection on the product

conveying lines and during product processing.

Also ensure ventilation on floor level during the storage and process

phases. Please make sure to read the “Material Safety Data Sheet”

(MSDS)

Snowa F300 is not suitable and not permitted for food contact

application.

Reviews

There are no reviews yet.