| MFI | 4 |

|---|

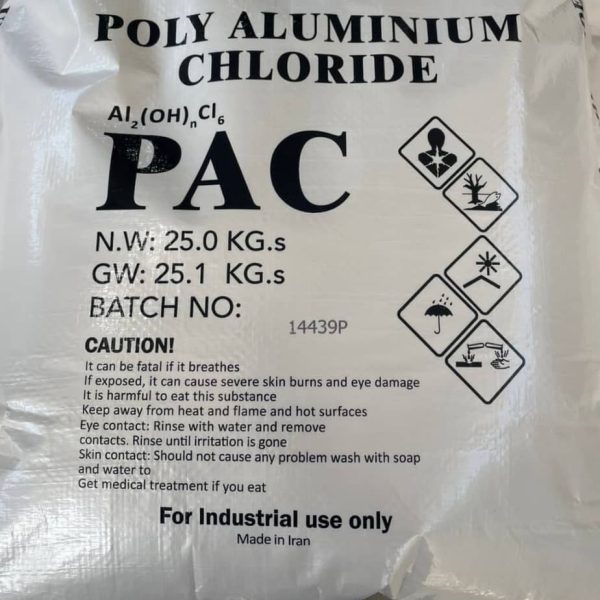

Poly Aluminum Chloride (PAC)

Price FCA: 500_520$Mt

Urmia Petrochemical Co URPC

Application:

Purification Processes:

•

Clarification and purification of drinking water

•

Municipal and human sewage

•

Effluent of pulp and paper industries

•

Removal of heavy metal and hazardous compounds from Effluents

•

Leachate of urban garbage

•

Effluents of slaughterhouse and meat processing industries

•

Effluents of power plants and steel industries

•

Effluents of sanitary and detergent industries

•

Effluents of textile and dyeing industries

•

Effluents of dairy, food, beverage and oil extraction industries Industrial applications:

•

Production of high-quality papers in the paper industries

•

Production of concrete with higher consistency

•

Increasing the quality and efficiency of detergents in detergent and cleaning industries

Packaging delivery and storage:

The solid product can be supplied in 25 kg double-layered bags with the logo of Persian Gulf Petrochemical Industries Company and the liquid can be supplied in tankers and 1000 Liter non-metallic protected tanks (IBD).

Solid product of this material should be protected from sunlight direct radiation on the bags and keep dry and away from moisture.

The liquid product is classified as acidic and corrosive materials, so the maintenance and storage of liquid Poly Aluminum Chloride is done in containers and tankers made of PE or PVC or GRP or FRP.

Also, all equipment and supplies for loading and unloading, such as pumps, pipes and hoses, must be resistant to acid containing chloride.

Petro chem

پلی الومینیوم کلراید پتروشیمی ارومیه

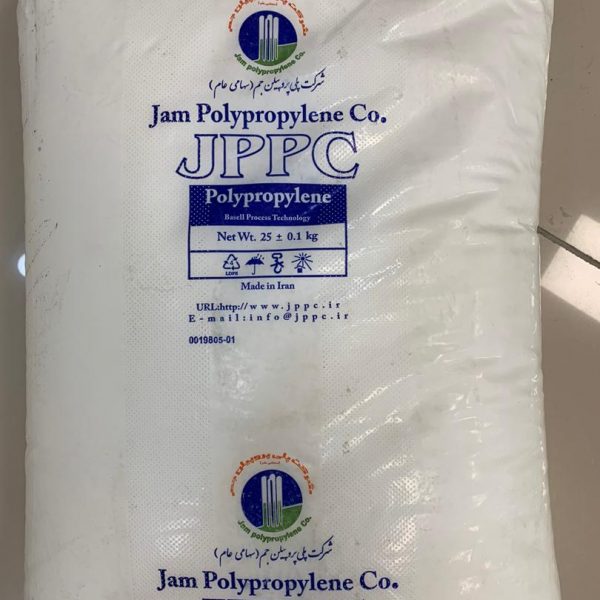

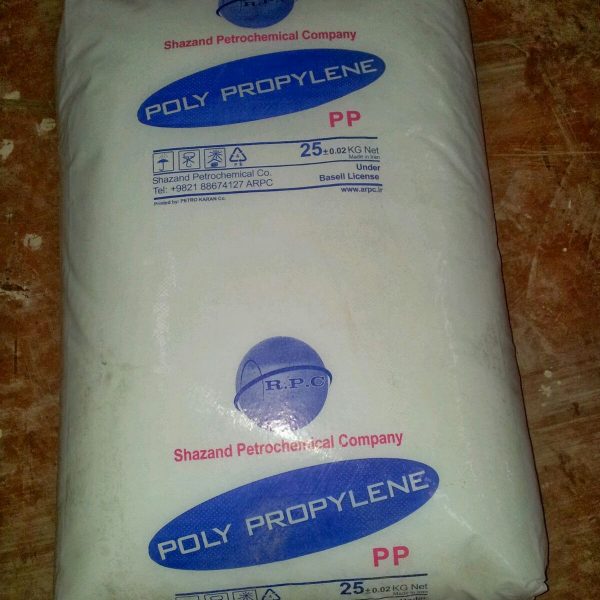

PP 1102XK (Raffia)

POLYMER TYPE : POLYPROPYLENE HOMOPOLYMER

GRADE NAME : RG 1102 XK

PACKING : PP bags of 25 kgs, 50 bags on a pallet shrinked by PE

APPLICATION : Raffia, tape yarn, technical textiles, carpet backing, diary products

PRODUCT FEATURES : Homopolymer with low water carry over and preferred grade for tapes

PROCESSING METHOD : Extrusion

PP 1102XL (Extrusion)

POLYMER TYPE : POLYPROPYLENE HOMOPOLYMER

GRADE NAME : RG 1102 XL

PACKING : PP bags of 25 kgs, 50 bags on a pallet shrinked by PE

APPLICATION : Extrusion and injection moulding applications, raffia, tapes, monofilaments, diary products

PRODUCT FEATURES : Homopolymer with general extrusion additivation

PROCESSING METHOD : Extrusion

PP 1104K (OPP)

POLYMER TYPE : POLYPROPYLENE HOMOPOLYMER

GRADE NAME : RG 1104 K

PACKING : PP bags of 25 kgs, 50 bags on a pallet shrinked by PE

APPLICATION : OPP films-metallizable (Stenter Frame Process), general extrusion

PRODUCT FEATURES : Homopolymer with narrow MFR range and low taste & odour

PROCESSING METHOD : Extrusion

PP 3212E (PIPE)

POLYMER TYPE : POLYPROPYLENE RANDOM COPOLYMER

GRADE NAME : RG 3212 E

PACKING : PP bags of 25 kgs, 50 bags on a pallet shrinked by PE

APPLICATION : Pressure pipes, hot & cold water system, drinking water pipes, pipes for electrical appliances

PRODUCT FEATURES : Random copolymer for extrusion applications with high melt stability

PROCESSING METHOD : Extrusion

PP 552R (Fiber)

Description:

″Jampilen HP552R″ is a high melt flow homopolymer for the

production of CF, BCF and fine denier staple fibers at medium

to high spinning speeds and exhibits excellent antigasfading

properties.

″Jampilen HP552R″ is suitable for nonwoven fabrics for

diapers, medical-sanitary applications and wipes. Another

typical application is high tenacity continuous filament for

straps for backpacks, sport bags, bulk bags and safety belts.

Continuous filament with medium tenacity is used for

upholstery and sportswear. ″Jampilen HP552R″ is also suited

for the production of bulked continuous filament for carpets.

″Jampilen HP552R″ is suitable for food contact.

Processing Method:

Fiber Extrusion (CF, BCF, staple)

Features:

High melt flow

Excellent antigasfading properties

Good processability

Homopolymer

Typical Applications:

Wipes and tissues

Straps for backpacks, sport bags, bulk bags and for safety belts

Upholstery and sportswear

Bulk continuous filament for carpets

Nonwoven staple fiber

Injection molded articles, housewares, etc

Approval: Food

PP RP210G (Blow molding)

POLYMER TYPE : Polypropylene random copolymer

GRADE NAME : PP RP210G

PACKING : PP bags of 25 kgs, 50 bags on a pallet shrinked by PE

APPLICATION : Moplen RP210G is a medium modified polypropylene random copolymer

designed for blow moulding and sheet & film extrusion.

It offers low density, stress cracking resistance and high chemical resistance.

Main applications of Moplen RP210G are extrusion of film for packaging & sheet

for stationery folders and displays, the extrusion blow moulding of high gloss

monolayer bottles, clear or pigmented, for the packaging of cosmetics,

detergents, chemicals and food-stuffs.

* Moplen RP210G is suitable for food contact.

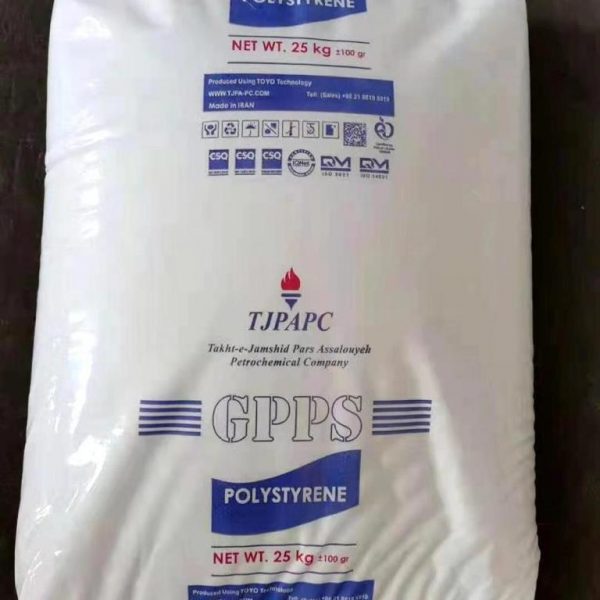

PS GPPS 1161 (MFI: 4)

General Purpose Polystyrene

This grade is high heat for PS foam.

Main Applications:

Parts for home electrical appliances (nameplates, transparent display covers for VTR, etc), Office stationary, Foamed PS, etc

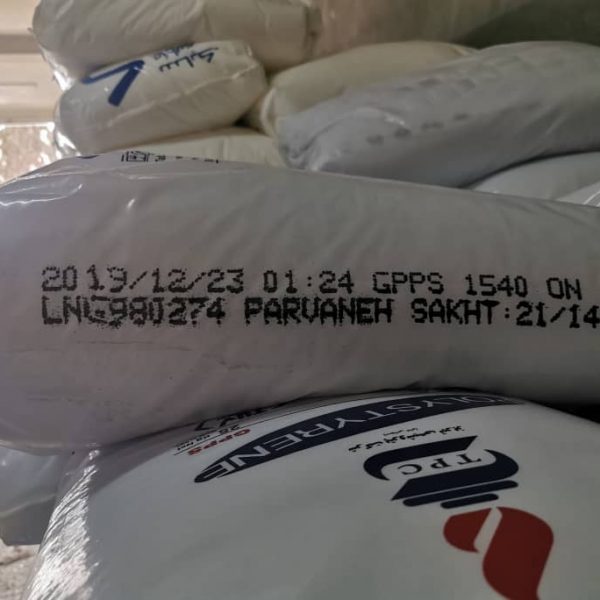

PS GPPS 1540 (MFI: 11)

General Information :

GPPS 1540 is an easy flowing crystal polystyrene designed for

extrusion or injection applications . In extrusion , it improves extruder

output and thermoforming cycle time when mixed with a super high

impact polystyrene such as HIPS 7240. It is particularly suitable for

glossy-layer co-extrusion.

It does combine excellent fluidity with a softening point higher

than GPPS 1810/1811 grade.

Applications :

Extrusion :Impact dilution; Gloss layer in co-extrusion; Anionic

styrene butadiene copolymer dilution.

Injection :Packaging articles; Medical applications,e.g., petri

dishes; Office equipment; Pen barrels; Crisper boxes for refrigerators;

Cups.

PS GPPS 1551 (MFI: 9)

General Purpose Polystyrene

This grade is high strength & high cycle polystyrene.

Main Applications:

Thin walled food Containers, Medical ware ( petri dishes etc), Office stationary, housewares, etc.

Rotational HDPE 3840UA

HD3840UA (Rotational Moulding)

Product Description:

HD3840UA is a linear, UV stabilized virgin medium density polyethylene

copolymer grade (MDPE), with a narrow molecular weight distribution.

HD3840UA is high density polyethylene copolymer containing butene-1(C4) as comonomer. It is suitable for use as rotational moulding applications.

Characteristics:

− High stiffness.

− Good impact stress.

− Whiteness.

− UV stabilized.

− Good Stress Cracking Resistance.

− Excellent process-ability.

− Excellent internal and external surface finish.

Typical applications are:

− Rotational moulded items with good stiffness, such as: Septic tanks and

Ordinary containers.

− Injection moulded technical parts and closure

HD3840UA is suitable for food contact.

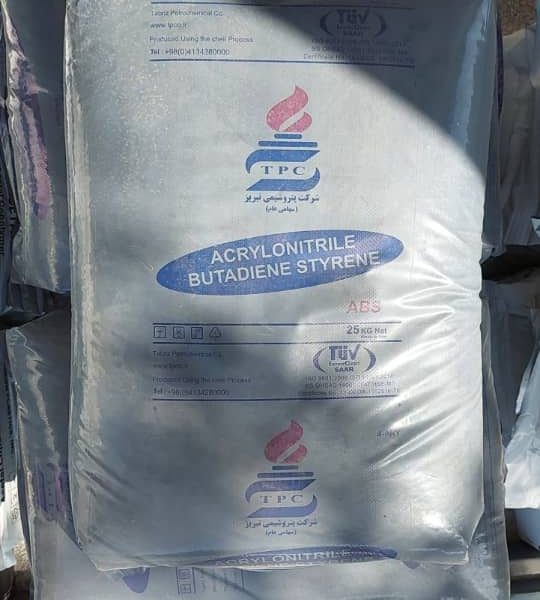

SD0150 ABS

Product Description :

General Purpose ABS, SD – 0150 grade, is a rigid thermoplastic with

good processing characteristics. It is a high flow injection molding

grade with considerable impact strength and medium heat deflection.

Applications :

This grade is intended for a wide range of applications including:

• auto parts,

• home appliances,

• electrical parts/fittings,

• Telecommunication and electronic devices.