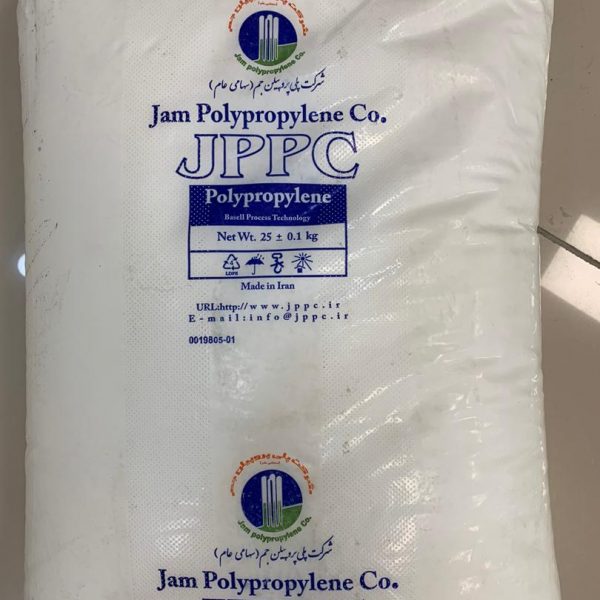

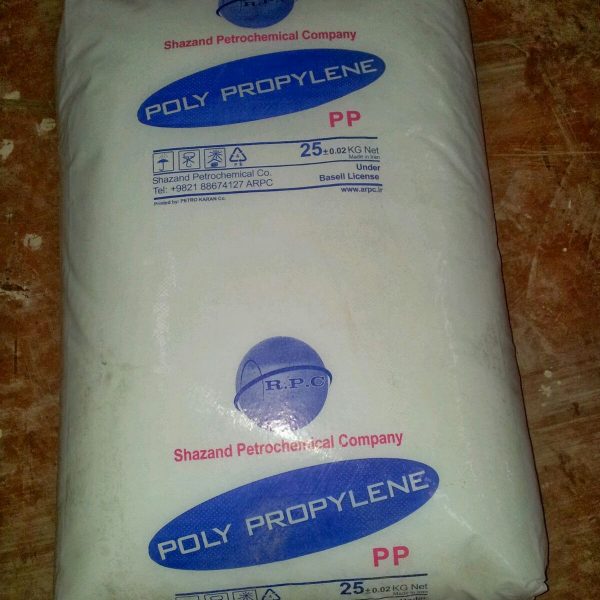

| MFI | 4 |

|---|

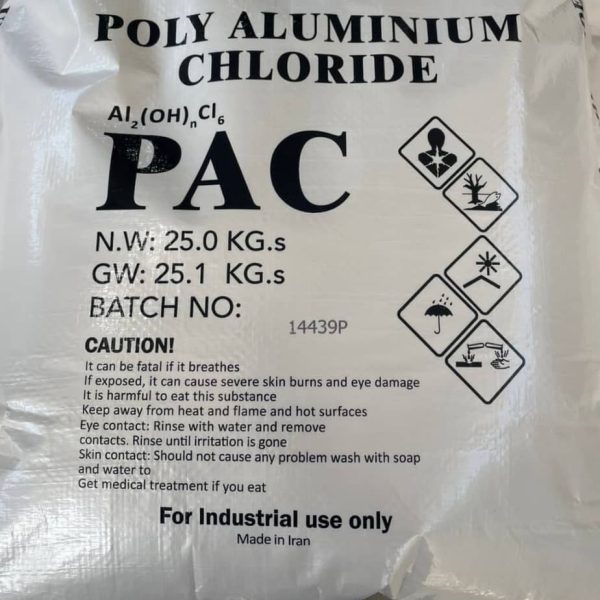

Poly Aluminum Chloride (PAC)

Price FCA: 500_520$Mt Urmia Petrochemical Co URPCApplication:Purification Processes:

•

Clarification and purification of drinking water

•

Municipal and human sewage

•

Effluent of pulp and paper industries

•

Removal of heavy metal and hazardous compounds from Effluents

•

Leachate of urban garbage

•

Effluents of slaughterhouse and meat processing industries

•

Effluents of power plants and steel industries•

Effluents of sanitary and detergent industries

•

Effluents of textile and dyeing industries

•

Effluents of dairy, food, beverage and oil extraction industries Industrial applications:

•

Production of high-quality papers in the paper industries

•

Production of concrete with higher consistency

•

Increasing the quality and efficiency of detergents in detergent and cleaning industries

Packaging delivery and storage:

The solid product can be supplied in 25 kg double-layered bags with the logo of Persian Gulf Petrochemical Industries Company and the liquid can be supplied in tankers and 1000 Liter non-metallic protected tanks (IBD).

Solid product of this material should be protected from sunlight direct radiation on the bags and keep dry and away from moisture.

The liquid product is classified as acidic and corrosive materials, so the maintenance and storage of liquid Poly Aluminum Chloride is done in containers and tankers made of PE or PVC or GRP or FRP.

Also, all equipment and supplies for loading and unloading, such as pumps, pipes and hoses, must be resistant to acid containing chloride.Petro chemپلی الومینیوم کلراید پتروشیمی ارومیه