| MFI | 0.9 |

|---|---|

| Density | 0.920 |

Liquid Paraffin / White Oil

FCA: 700_740 $Mt Industrial & Cosmetic GradeApplication:

Fiber emulsion , Insecticides , LubricantsPlastic production , Silicone oils , Paint stripperRubber & Tyre production , Solvents ,Furniture polishingDust control cleaning oils , Paper industryHousehold chemicals (polishes, creams, candles, etc.) , CosmeticsFood industry and agriculture (cheese-coating, poultry processing, fruit preservation, etc.)

وایت اویل همون پارافین مایع هست که ناخالصی ها رو ازش جدا کردن و هیچ ناخالصی نداره

دو مدل وایت اویل هست که یکیش حاصل از آیزوریسایکل تهران و یکیش هم حاصل از آیزو اصفهان

تفاوت این دو نوع در ویسکوزیته هست

پارافین مایع خام درواقع رنگبری نشده هست

و تفاوت در رنگ و ویسکوزیته هست

و پارافین مایع اصفهان رنگبری سختی داره

LLDPE 209AA AKPC (MFI: 0.9)

Download TDS Product Description:

“LL 0209AA” is a LLDPE copolymer with butene-1 as comonomer

which contains antioxidant.

It is recommended for general purpose applications.

It is suitable for blending with conventional LDPE.

Film made from pure LL 02090 AA has the following advantages

over conventional LDPE:

Better sealing,higher puncture resistance.

Greater drawdown capability.

Higher tensile strength.

Neutralizer: Calcium Stearate.

Antioxidant: Irganox1010, Irgafos168Application:Food Grade

Heave duty sacks, Agricultural films, liners.

Produce bags, Stretch film

LLDPE 209AA ARAK (MFI: 0.9)

Download TDS Main application & Characteristics:

LL0209AA are linear low density polyethylene copolymers containing butene-1

.as a co-monomerLL0209AA are suitable for general purpose films, neat or in lean blends with

LDPE and other ethylene polymers. Lean blends applications include sacks of all

. types, FFS and agricultural filmsIn lean blends they offer the following advantages:

− Greater draw down.

− Improved hot-tack and lower seal shrinkage.

− Better tear resistance.

− Higher tensile stress and elongation at break.LL0209AA should be stored in the dry condition below the 50°C and avoided

. from the exposure of direct sunlight

. Recommended melt temperature for extrusion is about 180°C - 225°C

.LL0209AA are suitable for food contact

LLDPE 22B02 (MFI: 2)

Download TDS Typical applications :

For use in lean and rich blend blown film application such as over wrap,

Counter bags, shrink film and boil in the bag applications

Artificial grass

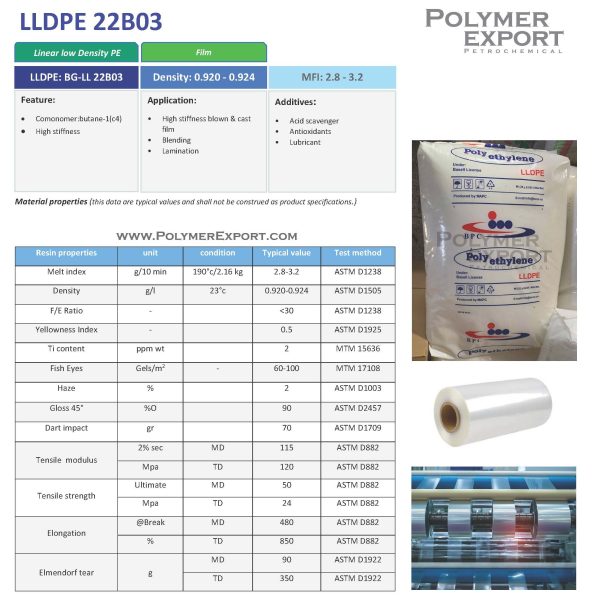

LLDPE 22B03 (MFI: 3)

Download TDS Application:

• High stiffness blown & cast

film

• Blending

• LaminationFeature:

Co monomer:butane-1(c4)

High stiffness Additives:

• Acid scavenger

• Antioxidants

• Lubricant

LLDPE 235F6 (MFI: 0.6)

FOB BND: 1000_1020 $Mt TDS PDF Download Data sheet Vision LLDPE 235F6 JPC JAM

Product Description:

LL-235F6 is a linear-low density polyethylene resin (LLDPE), obtained by gas

phase technology process. This grade designed for the production of different

type of films and agricultural tapes. In this grade excellent process ability,

mechanical properties, melt strength and draw ability achieved based on the

balanced molecular weight and molecular weight distribution. LL-235F6 has

good seal ability and approved for food contact applicationsApplication:• Agricultural Films and Tapes

• Lamination

• Shrink Film

• Industrial Films, Frozen Food Packaging Additives

•Thermal Antioxidant

(Process Stabilizer)

• Catalyst neutralizer

(acid scavenger, lubricant)

MEG _ Mono Ethylene Glycol _ Green Drum

week 27 Price CFR UAE : 570 $Mt HS CODE :29053100Mono Ethylene Glycol (MEG) is a colorless, odorless, viscous, and hygroscopic liquid belonging to the family of glycols. It is a type of ethylene glycol, produced through the reaction of ethylene oxide with water. MEG is one of the most widely used glycols and serves as a crucial raw material in various industrial applications.

Key Properties of MEG:

- Chemical Formula: C₂H₆O₂

- Molecular Weight: 62.07 g/mol

- Boiling Point: 197.6°C

- Freezing Point: -12.9°C

- Density: 1.113 g/cm³ at 20°C

- Miscibility: Completely miscible with water and many organic solvents

- Appearance: Clear, syrupy liquid

Applications of Mono Ethylene Glycol (MEG):

- Textile Industry:

- Used in the production of polyester fibers and fabrics.

- Acts as a raw material for polyester resins and polyethylene terephthalate (PET).

- Antifreeze and Coolants:

- Due to its low freezing point and high boiling point, MEG is a key ingredient in automotive antifreeze formulations.

- Used in HVAC systems to prevent freezing and corrosion.

- Plastic Industry:

- Major component in the manufacturing of PET, which is used in bottles, containers, and packaging materials.

- Chemical Intermediates:

- Used as a precursor in the synthesis of various chemical derivatives, including glycol ethers.

- Dehydration Agent:

- In natural gas processing, MEG is used to remove water from gas streams to prevent hydrate formation.

- Industrial and Consumer Products:

- Found in brake fluids, de-icing solutions, and as a solvent in inks and dyes.

Safety and Handling:

- MEG is toxic when ingested and can cause severe health issues, including central nervous system depression and kidney failure.

- Proper storage and handling practices include using protective equipment and ensuring good ventilation.

- In case of spills, containment and absorption using inert materials are recommended.

MEG _ Mono Ethylene Glycol _ Shazand Arak _ Marun

Price FCA: 500_540 $Mt MONOETHYLENEGLYCOL obtained from the reaction of ethylene oxide and

water. It is a clear, transparent and odorless liquid that can be mixed with

water in any proportion.Packing:

Bulk or in 220 Lit (net: 220 Kg) new drums, each 4 drums strapped on a pallet.IBC TANK , ISO TANK , BULKپتروشیمی شازند اراک و مارون و مروارید

MEG Recycle 99% ( Refined )

week 27 Price CFR UAE : 510 $Mt HS CODE :29053100Mono Ethylene Glycol (MEG) is a colorless, odorless, viscous, and hygroscopic liquid belonging to the family of glycols. It is a type of ethylene glycol, produced through the reaction of ethylene oxide with water. MEG is one of the most widely used glycols and serves as a crucial raw material in various industrial applications.

Key Properties of MEG:

- Chemical Formula: C₂H₆O₂

- Molecular Weight: 62.07 g/mol

- Boiling Point: 197.6°C

- Freezing Point: -12.9°C

- Density: 1.113 g/cm³ at 20°C

- Miscibility: Completely miscible with water and many organic solvents

- Appearance: Clear, syrupy liquid

Applications of Mono Ethylene Glycol (MEG):

- Textile Industry:

- Used in the production of polyester fibers and fabrics.

- Acts as a raw material for polyester resins and polyethylene terephthalate (PET).

- Antifreeze and Coolants:

- Due to its low freezing point and high boiling point, MEG is a key ingredient in automotive antifreeze formulations.

- Used in HVAC systems to prevent freezing and corrosion.

- Plastic Industry:

- Major component in the manufacturing of PET, which is used in bottles, containers, and packaging materials.

- Chemical Intermediates:

- Used as a precursor in the synthesis of various chemical derivatives, including glycol ethers.

- Dehydration Agent:

- In natural gas processing, MEG is used to remove water from gas streams to prevent hydrate formation.

- Industrial and Consumer Products:

- Found in brake fluids, de-icing solutions, and as a solvent in inks and dyes.

Safety and Handling:

- MEG is toxic when ingested and can cause severe health issues, including central nervous system depression and kidney failure.

- Proper storage and handling practices include using protective equipment and ensuring good ventilation.

- In case of spills, containment and absorption using inert materials are recommended.

Pars Carbon Black

N330 N660 N550Carbon black (subtypes are acetylene black, channel black, furnace black, lamp black and thermal black) is a material produced by the incomplete combustion of coal and coal tar, vegetable matter, or petroleum products, including fuel oil, fluid catalytic cracking tar, and ethylene cracking in a limited supply of air. Carbon black is a form of paracrystalline carbon that has a high surface-area-to-volume ratio, albeit lower than that of activated carbon. It is dissimilar to soot in its much higher surface-area-to-volume ratio and significantly lower (negligible and non-bioavailable) polycyclic aromatic hydrocarbon (PAH) content. However, carbon black can be used as a model compound for diesel soot to better understand how diesel soot behaves under various reaction conditions as carbon black and diesel soot have some similar properties such as particle sizes, densities, and copolymer adsorption abilities that contribute to them having similar behaviours under various reactions such as oxidation experiments. Carbon black is used as a colorant and reinforcing filler in tires and other rubber products; pigment and wear protection additive in plastics, paints.

The current International Agency for Research on Cancer (IARC) evaluation is that, “Carbon black is possibly carcinogenic to humans. Short-term exposure to high concentrations of carbon black dust may produce discomfort to the upper respiratory tract through mechanical irritation.

The most common use (70%) of carbon black is as a pigment and reinforcing phase in automobile tires. Carbon black also helps conduct heat away from the tread and belt area of the tire, reducing thermal damage and increasing tire life. In other uses, the structure and arrangement of carbon black contribute to its increased conductive properties that are useful in lithium-ion batteries. Its low cost makes it a common addition to cathodes and anodes and is considered a safe replacement to lithium metal in lithium-ion batteries. About 20% of world production goes into belts, hoses, and other non-tire rubber goods. The remaining 10% use of carbon black comes from pigment in inks, coatings, and plastics, as well as being used as a conductive additive in lithium-ion batteries.

Carbon black is added to polypropylene because it absorbs ultraviolet radiation, which otherwise causes the material to degrade. Carbon black particles are also employed in some radar absorbent materials, in photocopier and laser printer toner, and in other inks and paints. The high tinting strength and stability of carbon black has also provided use in coloring of resins and films. Carbon black has been used in various applications for electronics. A good conductor of electricity, carbon black is used as a filler mixed in plastics, elastomer, films, adhesives, and paints. It is used as an antistatic additive agent in automobile fuel caps and pipes.