| MFI | 0.33 |

|---|

HEX 4460 PE80+

Download TDS Product Description:

HEX 4460 PE80+ is a high molecular weight, high-density polyethylene (HDPE) with high melt viscosity for extrusion. This grade, which is produced by 1-hexene co-monomer, is classified as PE 80+ and provides excellent stress crack resistance properties (ESCR) combined with very good long-term hydrostatic strength and good process-ability.Application

Drinking Water Pipe, Drainage Pipe, Plumbing

Form(s)

PelletAttribute

Outstanding ESCR

Good Resistance to SCG & RCP

Good Creep Strength

Good Process-ability

Good Chemical Resistance

Very Good Low Temp. Impact ResistanceAdditives

Processing Aid: No

Antioxidant: Yes

Antiblock: No

Slip Agent: No

Hypochlorite Calcium % 65-70

This chemical is a white and dry granular with a purity of %65-%70. Calcium hypochlorite granules dissolve in water easily and are mainly used in water treatment for disinfection and removal of bacteria, algae and micro-organisms.

Physical specifications: White color solid granule, strong odor of chlorine. Soluble in water and alcohol with a strong reaction characteristic Stability and reactions: In high temperature is unstable. Reacts rapidly with oils and organic materials and is flammable. Handling and storage: Keep away from incompatible materials, reducing substances, organic materials, acids, combustible materials. Keep in cool and dry places. Environmental precautions: In case of spreading, collect and keep in containers having no incompatible materials. Packing and delivery: 25 kg containers

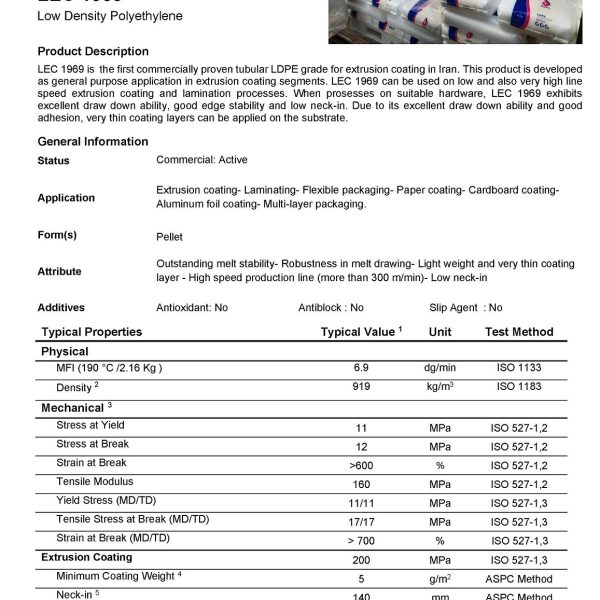

LDPE 1969 (MFI: 6.9)

Download TDS Product Description:

LEC 1969 is the first commercially proven tubular LDPE grade for extrusion coating in Iran. This product is developed

as general purpose application in extrusion coating segments. LEC 1969 can be used on low and also very high line

speed extrusion coating and lamination processes. When prosesses on suitable hardware, LEC 1969 exhibits

excellent draw down ability, good edge stability and low neck-in. Due to its excellent draw down ability and good

adhesion, very thin coating layers can be applied on the substrate.Applications:Extrusion coating- Laminating- Flexible packaging- Paper coating- Cardboard coating-

Aluminum foil coating- Multi-layer packaging.Status: Commercial: ActiveForm(s): PelletAttribute:

Outstanding melt stability- Robustness in melt drawing- Light weight and very thin coating layer - High speed production line (more than 300 m/min)- Low neck-inAdditives:

Antioxidant: No

Antiblock : No

Slip Agent : No

LDPE 2047A (MFI: 4.7)

TDS PDF Download Data sheet Vision Product Description:

LFI2047A is a low density polyethylene, with good toughness and good optical properties. This product offers a medium level of antiblock and slip agent (Erucamide), low energy consumption during processing and a good draw down ability. It typically exhibits low friction and low blocking. LFI2047A has been manufactured under SABTEC licensed technology.Applications:Blown film extrusion, high clarity laundry bag, textile wrapping film, zip lock bagStatus: Commercial: ActiveForm(s): PelletAttribute:

Good toughness, high speed converting without sticking, good optical propertiesAdditives:

Antioxidant: Yes

Antiblock : Yes

Slip Agent : Yes

LDPE 2100 (MFI: 0.3)

Download TDS Product Description:

LDPE L2100TN00 is low density polyethylene for production of general purpose film.Applications:Grade with excellent toughness and tear strength and outstanding shrink properties.very low energy

consumption during processing and has excellent draw down ability.The material contains no additives and is suitable for application in shrinkhoods,industrial sacks,heavy duty carrier bags and linersAdditives: Anti oxidant

consumption during processing and has excellent draw down ability.The material contains no additives and is suitable for application in shrinkhoods,industrial sacks,heavy duty carrier bags and linersAdditives: Anti oxidant

LDPE 2102 (MFI: 1.9)

Download TDS Product Description:

LDPE 2102TX00 is low density polyethylene for production of general purpose film.Applications:For general purpose film without additives.used in a wide range of widths and thicknesses for pouches ,bags , liners and lamination film.Additives:

Anti oxidant

LDPE 2119 (MFI: 1.9)

Download TDS Product Description:LFI2119 is a low-density polyethylene, with excellent optical properties. This grade offers high output and excellent drawdown and specially designed for general-purpose thin films. LFI2119 has been manufactured under SABTEC licensed technology.Applications:Blown film extrusion, packaging film, general lamination filmStatus: Commercial: ActiveForm(s): PelletAttribute:

Very good optical properties, good toughness, good melt strengthAdditives:

Antioxidant: Yes

Antiblock : No

Slip Agent : No

LDPE 2125A (MFI: 2.5)

TDS PDF Download Data sheet Vision Product Description

LFI2125A is a low density polyethylene, with a medium level of anti-block and slip agent (Erucamide). This grade offers good optical properties, low energy consumption during processing, adequate COF level and excellent draw down. LFI2125A has been manufactured under SABTEC licensed technology.Applications:Blown film extrusion, packaging film for food and goods, general lamination film.Status: Commercial: ActiveForm(s): PelletAttribute:

Good toughness, high speed converting without sticking, good optical properties, suitable when ultimate down gauging is required.Additives:

Antioxidant: Yes

Antiblock : Yes

Slip Agent : Yes

LDPE 2130 (MFI: 0.3)

Download TDS Product Description:

LFI2130 is a high molecular weight, low density polyethylene for producing heavy-duty packaging films for applications like shrink hoods. It contains no slip agent and antiblock additives. It gives outstanding strength and toughness, draw down ability and very good biaxial shrink properties. LFI2130 has been manufactured under SABTEC licensed technology.Applications:Blown film extrusion, heavy duty packaging film, shrink hoods, industrial sacks, carrier bag and liners.Status: Commercial: ActiveForm(s): PelletAttribute:

Good strenght and toughness, very good melt strength.Additives:

Antioxidant: Yes

Antiblock : No

Slip Agent : No

LDPE 2420D (MFI: 0.25)

Download TDS Product Description:

Lupolen 2420 D is a non -additivated,low density Polyethylene.It is delivered in

pellet form.Applications:Food Grade

Bags & Pouches

Bottles for Consumer Goods

Shrink Film

Blown Film

FilmProcessing Method:Blown Film

Injection Moulding

Extrusion Blow MouldingFeatures: Good Processability, Good Tear strength, Good Toughness

LDPE 2420H (MFI: 1.9)

Download TDS Product Description:

Lupolen 2420 H is a non -additivated,low density Polyethylene.It is delivered in

pellet form.Applications:Bags & Pouches , Film , Shrink Film , Blown Film , Cast FilmProcessing Method: Cast Film , Blown FilmFeatures: Good Heat Seal, Optical, Good Processability