VAM

Vinyl Acetate Monomer

VINYLACETATE is a colourless, low-viscous, flammable liquid with an ester-like

odour. It is miscible with a number of solvents, but not with water. The vapour is

invisible and being heavier than air, it spreads out at floor level. VINYL ACETATE

forms explosive mixtures with air.

Category: Petrochemicals

Tags: Arpc, Export, VAM, Vinyl Acetate Monomer, VINYLACETATE

Related products

PP 3212E (PIPE)

| MFI |

0.25 |

|---|

PP 1102XL (Extrusion)

| MFI |

5.5 |

|---|

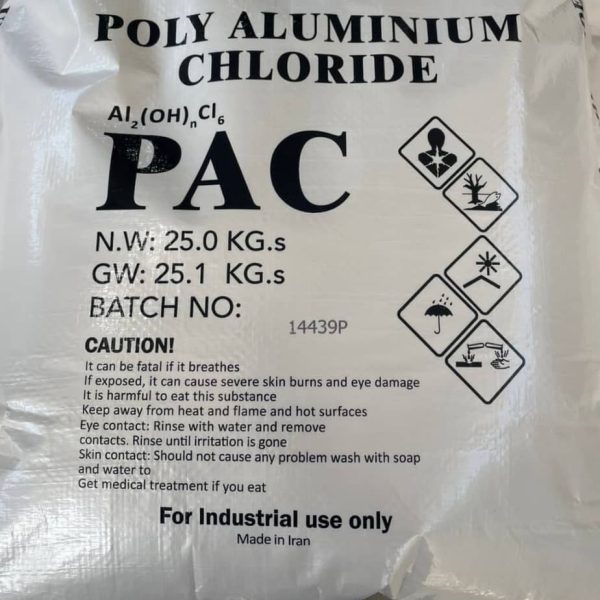

Poly Aluminum Chloride (PAC)

Price FCA: 500_520$Mt

Urmia Petrochemical Co URPC

Application:

Purification Processes:

•

Clarification and purification of drinking water

•

Municipal and human sewage

•

Effluent of pulp and paper industries

•

Removal of heavy metal and hazardous compounds from Effluents

•

Leachate of urban garbage

•

Effluents of slaughterhouse and meat processing industries

•

Effluents of power plants and steel industries

•

Effluents of sanitary and detergent industries

•

Effluents of textile and dyeing industries

•

Effluents of dairy, food, beverage and oil extraction industries Industrial applications:

•

Production of high-quality papers in the paper industries

•

Production of concrete with higher consistency

•

Increasing the quality and efficiency of detergents in detergent and cleaning industries

Packaging delivery and storage:

The solid product can be supplied in 25 kg double-layered bags with the logo of Persian Gulf Petrochemical Industries Company and the liquid can be supplied in tankers and 1000 Liter non-metallic protected tanks (IBD).

Solid product of this material should be protected from sunlight direct radiation on the bags and keep dry and away from moisture.

The liquid product is classified as acidic and corrosive materials, so the maintenance and storage of liquid Poly Aluminum Chloride is done in containers and tankers made of PE or PVC or GRP or FRP.

Also, all equipment and supplies for loading and unloading, such as pumps, pipes and hoses, must be resistant to acid containing chloride.

Petro chem

پلی الومینیوم کلراید پتروشیمی ارومیه

MEG Recycle 99% ( Refined )

week 27 Price CFR UAE : 510 $Mt

HS CODE :29053100

Mono Ethylene Glycol (MEG) is a colorless, odorless, viscous, and hygroscopic liquid belonging to the family of glycols. It is a type of ethylene glycol, produced through the reaction of ethylene oxide with water. MEG is one of the most widely used glycols and serves as a crucial raw material in various industrial applications.

IBC TANK , ISO TANK , BULK

Key Properties of MEG:

- Chemical Formula: C₂H₆O₂

- Molecular Weight: 62.07 g/mol

- Boiling Point: 197.6°C

- Freezing Point: -12.9°C

- Density: 1.113 g/cm³ at 20°C

- Miscibility: Completely miscible with water and many organic solvents

- Appearance: Clear, syrupy liquid

Applications of Mono Ethylene Glycol (MEG):

- Textile Industry:

- Used in the production of polyester fibers and fabrics.

- Acts as a raw material for polyester resins and polyethylene terephthalate (PET).

- Antifreeze and Coolants:

- Due to its low freezing point and high boiling point, MEG is a key ingredient in automotive antifreeze formulations.

- Used in HVAC systems to prevent freezing and corrosion.

- Plastic Industry:

- Major component in the manufacturing of PET, which is used in bottles, containers, and packaging materials.

- Chemical Intermediates:

- Used as a precursor in the synthesis of various chemical derivatives, including glycol ethers.

- Dehydration Agent:

- In natural gas processing, MEG is used to remove water from gas streams to prevent hydrate formation.

- Industrial and Consumer Products:

- Found in brake fluids, de-icing solutions, and as a solvent in inks and dyes.

Safety and Handling:

- MEG is toxic when ingested and can cause severe health issues, including central nervous system depression and kidney failure.

- Proper storage and handling practices include using protective equipment and ensuring good ventilation.

- In case of spills, containment and absorption using inert materials are recommended.

| purity |

99.8% |

|---|

MEG _ Mono Ethylene Glycol _ Green Drum

week 27 Price CFR UAE : 570 $Mt

HS CODE :29053100

Mono Ethylene Glycol (MEG) is a colorless, odorless, viscous, and hygroscopic liquid belonging to the family of glycols. It is a type of ethylene glycol, produced through the reaction of ethylene oxide with water. MEG is one of the most widely used glycols and serves as a crucial raw material in various industrial applications.

IBC TANK , ISO TANK , BULK

Key Properties of MEG:

- Chemical Formula: C₂H₆O₂

- Molecular Weight: 62.07 g/mol

- Boiling Point: 197.6°C

- Freezing Point: -12.9°C

- Density: 1.113 g/cm³ at 20°C

- Miscibility: Completely miscible with water and many organic solvents

- Appearance: Clear, syrupy liquid

Applications of Mono Ethylene Glycol (MEG):

- Textile Industry:

- Used in the production of polyester fibers and fabrics.

- Acts as a raw material for polyester resins and polyethylene terephthalate (PET).

- Antifreeze and Coolants:

- Due to its low freezing point and high boiling point, MEG is a key ingredient in automotive antifreeze formulations.

- Used in HVAC systems to prevent freezing and corrosion.

- Plastic Industry:

- Major component in the manufacturing of PET, which is used in bottles, containers, and packaging materials.

- Chemical Intermediates:

- Used as a precursor in the synthesis of various chemical derivatives, including glycol ethers.

- Dehydration Agent:

- In natural gas processing, MEG is used to remove water from gas streams to prevent hydrate formation.

- Industrial and Consumer Products:

- Found in brake fluids, de-icing solutions, and as a solvent in inks and dyes.

Safety and Handling:

- MEG is toxic when ingested and can cause severe health issues, including central nervous system depression and kidney failure.

- Proper storage and handling practices include using protective equipment and ensuring good ventilation.

- In case of spills, containment and absorption using inert materials are recommended.

| purity |

99.8% |

|---|

PP 1102XK (Raffia)

| MFI |

4 |

|---|

MEG _ Mono Ethylene Glycol _ Shazand Arak _ Marun

Price FCA: 500_540 $Mt

MONOETHYLENEGLYCOL obtained from the reaction of ethylene oxide and

water. It is a clear, transparent and odorless liquid that can be mixed with

water in any proportion.

Packing:

Bulk or in 220 Lit (net: 220 Kg) new drums, each 4 drums strapped on a pallet.

IBC TANK , ISO TANK , BULK

پتروشیمی شازند اراک و مارون و مروارید

| purity |

99.8% |

|---|

Tri Ethylene glycol _TEG

Tri Ethylene glycol

(TEG) is a colorless, odorless, viscous liquid belonging to the glycol family. It has a high boiling point, low volatility, and hygroscopic properties, making it useful in several industries.

Main Applications of Triethylene Glycol (TEG):

- Gas DehydTriethylene glycol ration (Natural Gas Industry)

- Plasticizer in Polymers

- Solvent

- Humectant

- Heat Transfer Fluid

- Disinfectant and Air Sanitizer

- Chemical Intermediate

- Lubricants and Hydraulic Fluids