PP RP210G (Blow molding)

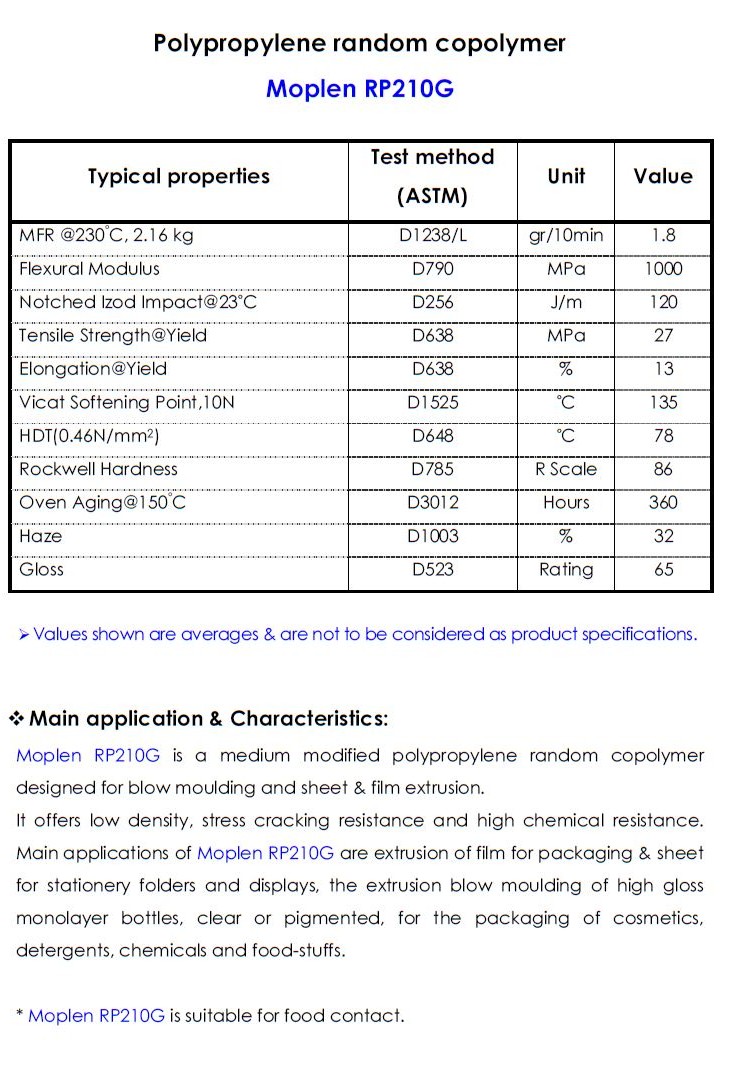

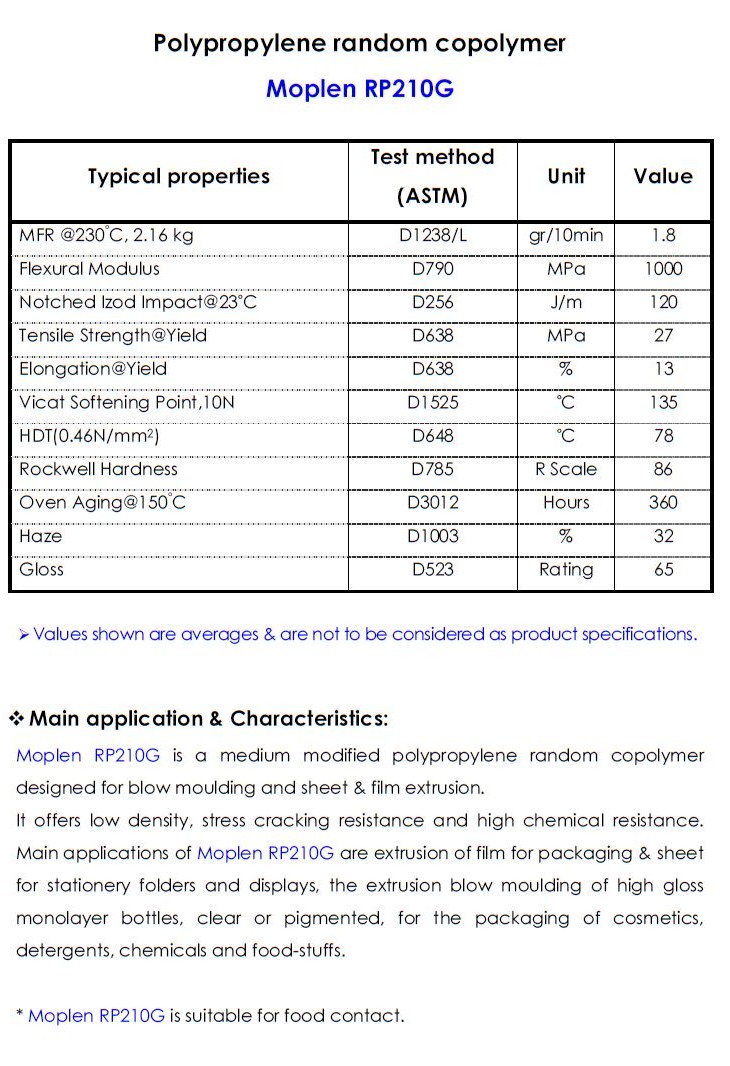

POLYMER TYPE : Polypropylene random copolymer

GRADE NAME : PP RP210G

PACKING : PP bags of 25 kgs, 50 bags on a pallet shrinked by PE

APPLICATION : Moplen RP210G is a medium modified polypropylene random copolymer

designed for blow moulding and sheet & film extrusion.

It offers low density, stress cracking resistance and high chemical resistance.

Main applications of Moplen RP210G are extrusion of film for packaging & sheet

for stationery folders and displays, the extrusion blow moulding of high gloss

monolayer bottles, clear or pigmented, for the packaging of cosmetics,

detergents, chemicals and food-stuffs.

* Moplen RP210G is suitable for food contact.

| MFI |

1.8 |

|---|

Related products

EPS F300

| Bead size - Diamenter |

0.7 – 0.9 mm |

|---|

HDPE 52518 (Injection)

| MFI |

18 |

|---|---|

| Density |

0.952 |

HDPE 7000F Mehr ( MHPC )

| MFI |

0.04 |

|---|---|

| Density |

0.954 |

HDPE BL3 JAM (BlowMolding)

| MFI |

23 |

|---|---|

| Density |

0.954 |

PP 3212E (PIPE)

| MFI |

0.25 |

|---|

SD0150 ABS

| MFI |

1.7 |

|---|

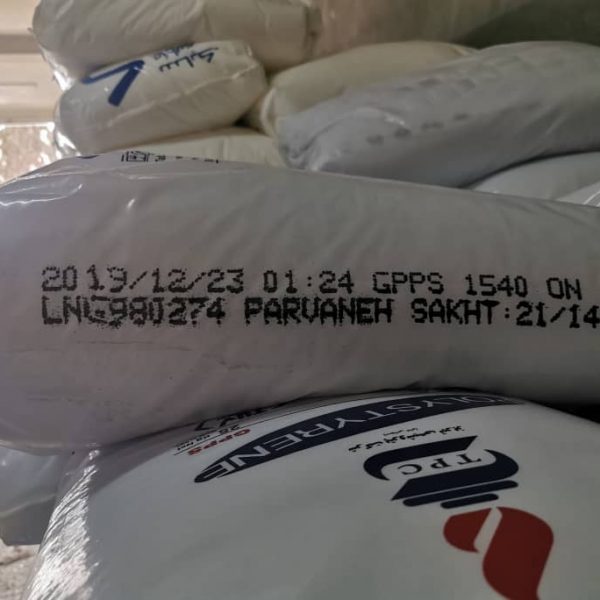

PS GPPS 1540 (MFI: 11)

| MFI |

11 |

|---|

LDPE 2420D (MFI: 0.25)

| MFI |

0.25 |

|---|---|

| Density |

0.923 |

Reviews

There are no reviews yet.