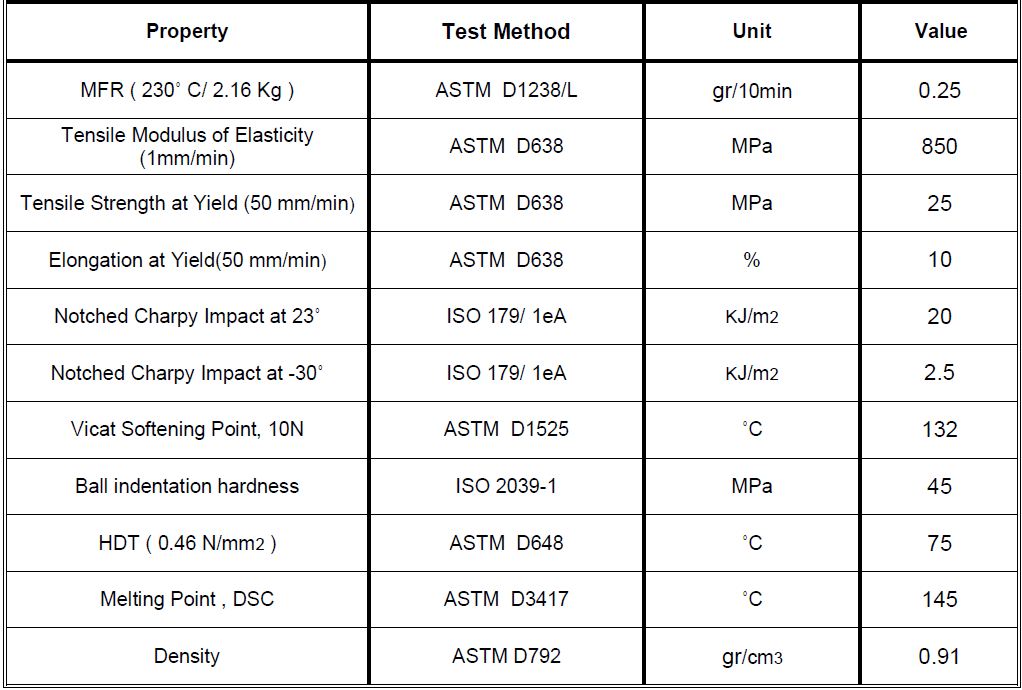

PP 3212E (PIPE)

POLYMER TYPE : POLYPROPYLENE RANDOM COPOLYMER

GRADE NAME : RG 3212 E

PACKING : PP bags of 25 kgs, 50 bags on a pallet shrinked by PE

APPLICATION : Pressure pipes, hot & cold water system, drinking water pipes, pipes for electrical appliances

PRODUCT FEATURES : Random copolymer for extrusion applications with high melt stability

PROCESSING METHOD : Extrusion

Description

Additional information

| MFI |

0.25 |

|---|

Reviews (0)

Be the first to review “PP 3212E (PIPE)” Cancel reply

Related products

LLDPE 22B02 (MFI: 2)

Download TDS

Typical applications :

For use in lean and rich blend blown film application such as over wrap,

Counter bags, shrink film and boil in the bag applications

Artificial grass

| MFI |

2 |

|---|---|

| Density |

0.920 |

PS GPPS 1161 (MFI: 4)

PP 1104K (OPP)

| MFI |

3.2 |

|---|

PP 1102XK (Raffia)

| MFI |

4 |

|---|

PP 1102XL (Extrusion)

| MFI |

5.5 |

|---|

HDPE 54B04 (Injection)

EPS F300

| Bead size - Diamenter |

0.7 – 0.9 mm |

|---|

Reviews

There are no reviews yet.