PP 1104K (OPP)

POLYMER TYPE : POLYPROPYLENE HOMOPOLYMER

GRADE NAME : RG 1104 K

PACKING : PP bags of 25 kgs, 50 bags on a pallet shrinked by PE

APPLICATION : OPP films-metallizable (Stenter Frame Process), general extrusion

PRODUCT FEATURES : Homopolymer with narrow MFR range and low taste & odour

PROCESSING METHOD : Extrusion

Categories: POLYMERS, Polypropylene

Tags: 1102xk, Export, Extrusion, HOMOPOLYMER, OPP

Description

Additional information

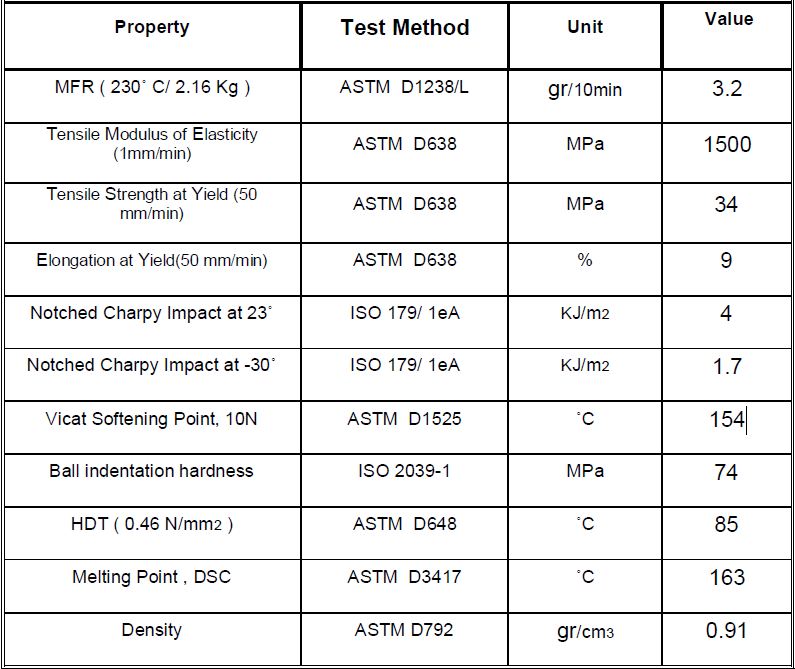

| MFI |

3.2 |

|---|

Reviews (0)

Be the first to review “PP 1104K (OPP)” Cancel reply

Related products

LDPE 2119 (MFI: 1.9)

Download TDS

Product Description:

LFI2119 is a low-density polyethylene, with excellent optical properties. This grade offers high output and excellent drawdown and specially designed for general-purpose thin films. LFI2119 has been manufactured under SABTEC licensed technology.

Applications:

Blown film extrusion, packaging film, general lamination film

Status: Commercial: Active

Form(s): Pellet

Attribute:

Very good optical properties, good toughness, good melt strength

Additives:

Antioxidant: Yes

Antiblock : No

Slip Agent : No

| MFI |

1.9 |

|---|

HDPE 54B04 (Injection)

LDPE 2130 (MFI: 0.3)

Download TDS

Product Description:

LFI2130 is a high molecular weight, low density polyethylene for producing heavy-duty packaging films for applications like shrink hoods. It contains no slip agent and antiblock additives. It gives outstanding strength and toughness, draw down ability and very good biaxial shrink properties. LFI2130 has been manufactured under SABTEC licensed technology.

Applications:

Blown film extrusion, heavy duty packaging film, shrink hoods, industrial sacks, carrier bag and liners.

Status: Commercial: Active

Form(s): Pellet

Attribute:

Good strenght and toughness, very good melt strength.

Additives:

Antioxidant: Yes

Antiblock : No

Slip Agent : No

| MFI |

0.3 |

|---|---|

| Density |

921 |

PS GPPS 1161 (MFI: 4)

PP 1102XK (Raffia)

| MFI |

4 |

|---|

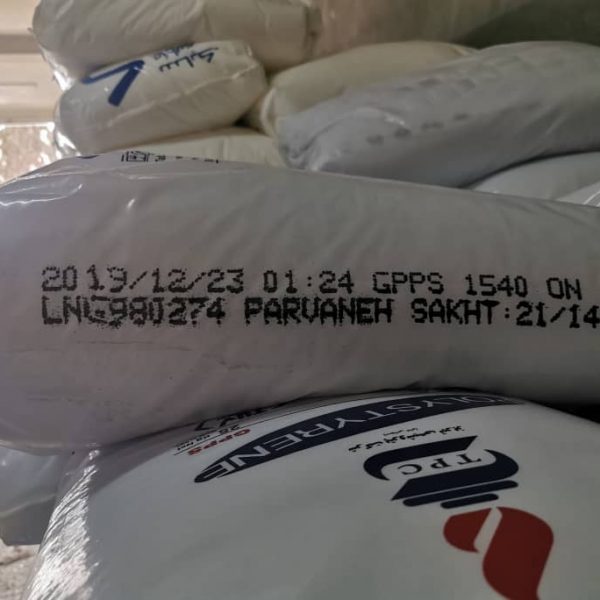

PS GPPS 1540 (MFI: 11)

| MFI |

11 |

|---|

HDPE CRP100N (PIPE)

Download TDS

HM-CRP100N (PE100) is a natural pipe grade resin which

is manufactured by suspension polymerization of ethylen

monomer, HM-CRP100N )PE100) is a bi-model high density

polyethylene with 1-Butene as co monomer.

Main Applications

• Top quality PE100 pressure

• Pipes for gas and water

transportaion at higher pressures

or with thinner walls as PE80 (UV

stabilization and/ or pigments during

precessing)

Characteristic

Properties

• Natural PE100 pipe resin.

Additives

• Antioxidant/Process stabilizer

• Lubricant (processing aid)/ acid

scavenger

| MFI |

0.22 |

|---|

LDPE 2100 (MFI: 0.3)

Download TDS

Product Description:

LDPE L2100TN00 is low density polyethylene for production of general purpose film.

Applications:

Grade with excellent toughness and tear strength and outstanding shrink properties.very low energy

consumption during processing and has excellent draw down ability.The material contains no additives and is suitable for application in shrinkhoods,industrial sacks,heavy duty carrier bags and liners Additives: Anti oxidant

consumption during processing and has excellent draw down ability.The material contains no additives and is suitable for application in shrinkhoods,industrial sacks,heavy duty carrier bags and liners Additives: Anti oxidant

| MFI |

0.3 |

|---|---|

| Density |

921 |

Reviews

There are no reviews yet.