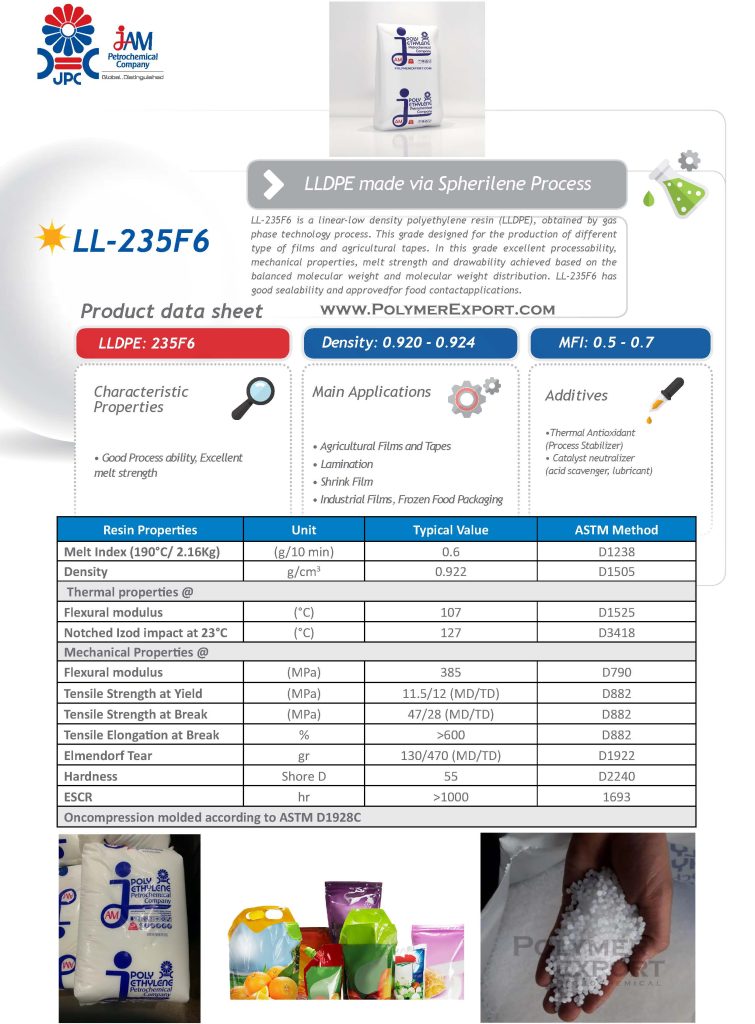

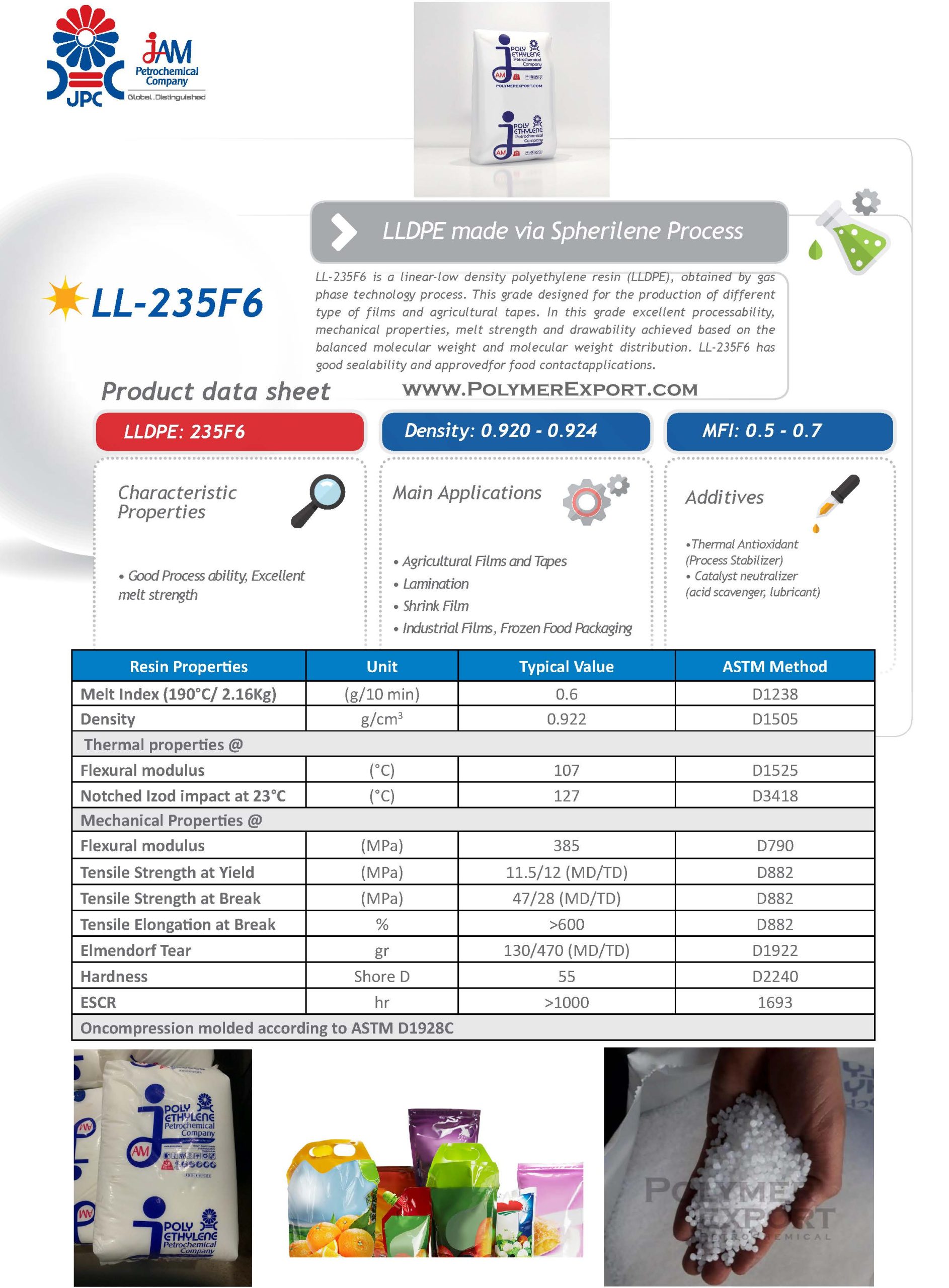

LLDPE 235F6 (MFI: 0.6)

LLDPE 235F6 JPC JAM

Product Description:

LL-235F6 is a linear-low density polyethylene resin (LLDPE), obtained by gas

phase technology process. This grade designed for the production of different

type of films and agricultural tapes. In this grade excellent process ability,

mechanical properties, melt strength and draw ability achieved based on the

balanced molecular weight and molecular weight distribution. LL-235F6 has

good seal ability and approved for food contact applications

Application:

• Agricultural Films and Tapes

• Lamination

• Shrink Film

• Industrial Films, Frozen Food Packaging

Additives

•Thermal Antioxidant

(Process Stabilizer)

• Catalyst neutralizer

(acid scavenger, lubricant)

| MFI |

0.6 |

|---|---|

| Density |

0.922 |

Related products

PP 1102XK (Raffia)

| MFI |

4 |

|---|

PP 1102XL (Extrusion)

| MFI |

5.5 |

|---|

LDPE 2119 (MFI: 1.9)

| MFI |

1.9 |

|---|

PS GPPS 1551 (MFI: 9)

HDPE 52518 (Injection)

| MFI |

18 |

|---|---|

| Density |

0.952 |

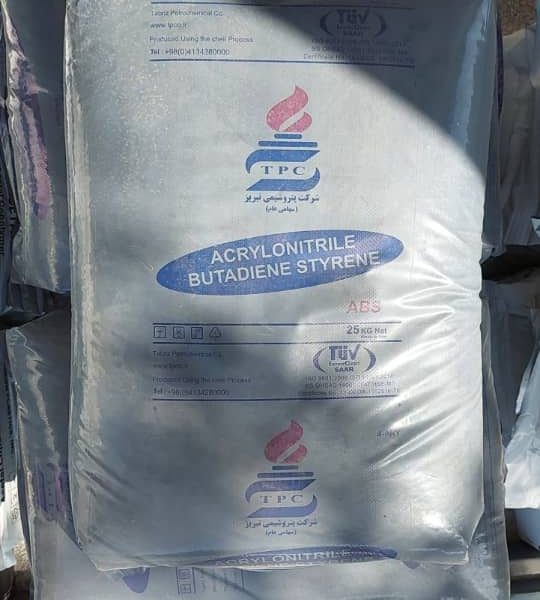

SD0150 ABS

| MFI |

1.7 |

|---|

Rotational HDPE 3840UA

| MFI |

4 |

|---|

LDPE 2100 (MFI: 0.3)

consumption during processing and has excellent draw down ability.The material contains no additives and is suitable for application in shrinkhoods,industrial sacks,heavy duty carrier bags and liners Additives: Anti oxidant

| MFI |

0.3 |

|---|---|

| Density |

921 |

Reviews

There are no reviews yet.