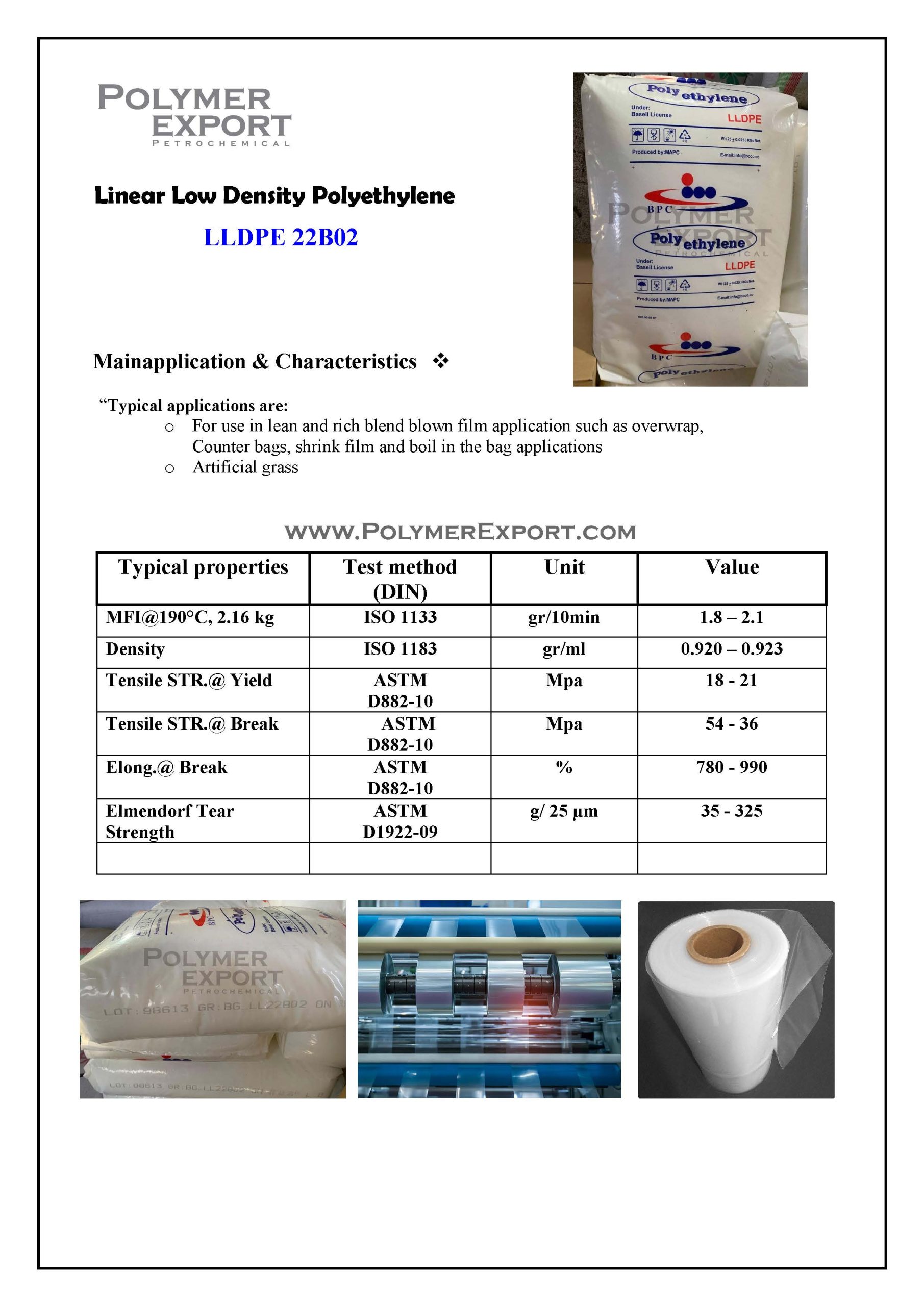

LLDPE 22B02 (MFI: 2)

Download TDS

Typical applications :

For use in lean and rich blend blown film application such as over wrap,

Counter bags, shrink film and boil in the bag applications

Artificial grass

Categories: LLDPE, POLYMERS

Tags: BCCO, BLOWN FILM, LLDPE 22B02, MAHABAD, Shrink Film

Related products

PP 3212E (PIPE)

| MFI |

0.25 |

|---|

PP 1102XL (Extrusion)

| MFI |

5.5 |

|---|

HDPE BL3 JAM (BlowMolding)

Download TDS

HF-4760(BL3) is a blow molding grade resin with high density polyethylene with

1-Butene as co monomer which is manufactured by the suspension polymerization

of ethylene monomer. Stiffness, good ESCR are it's spetial properties. High

rigidity and good flowablity which made it proper for usage in bottles and small

blow molding goods.

Applications

Small blow moulding

Bottles

Containers (up to 5 lit )

Packing of pharmaceuticals & surfactants

Additives:

• Antioxidant/Process stabilizer

• Lubricant/ acid scavenger

Features:

• High density and Stiffness, good

flowabilitty and impact Stvength

and good Stvess Cvacking resistance.

| MFI |

23 |

|---|---|

| Density |

0.954 |

HDPE CRP100N (PIPE)

Download TDS

HM-CRP100N (PE100) is a natural pipe grade resin which

is manufactured by suspension polymerization of ethylen

monomer, HM-CRP100N )PE100) is a bi-model high density

polyethylene with 1-Butene as co monomer.

Main Applications

• Top quality PE100 pressure

• Pipes for gas and water

transportaion at higher pressures

or with thinner walls as PE80 (UV

stabilization and/ or pigments during

precessing)

Characteristic

Properties

• Natural PE100 pipe resin.

Additives

• Antioxidant/Process stabilizer

• Lubricant (processing aid)/ acid

scavenger

| MFI |

0.22 |

|---|

PP 1104K (OPP)

| MFI |

3.2 |

|---|

SD0150 ABS

| MFI |

1.7 |

|---|

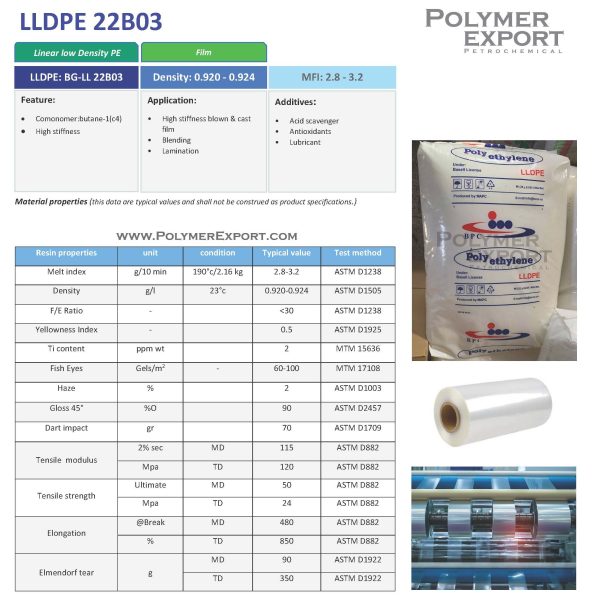

LLDPE 22B03 (MFI: 3)

Download TDS

Application:

• High stiffness blown & cast

film

• Blending

• Lamination

Feature:

Co monomer:butane-1(c4)

High stiffness

Additives:

• Acid scavenger

• Antioxidants

• Lubricant

| MFI |

3 |

|---|---|

| Density |

0.920 |

LDPE 2130 (MFI: 0.3)

Download TDS

Product Description:

LFI2130 is a high molecular weight, low density polyethylene for producing heavy-duty packaging films for applications like shrink hoods. It contains no slip agent and antiblock additives. It gives outstanding strength and toughness, draw down ability and very good biaxial shrink properties. LFI2130 has been manufactured under SABTEC licensed technology.

Applications:

Blown film extrusion, heavy duty packaging film, shrink hoods, industrial sacks, carrier bag and liners.

Status: Commercial: Active

Form(s): Pellet

Attribute:

Good strenght and toughness, very good melt strength.

Additives:

Antioxidant: Yes

Antiblock : No

Slip Agent : No

| MFI |

0.3 |

|---|---|

| Density |

921 |