LLDPE 209AA AKPC (MFI: 0.9)

Download TDS

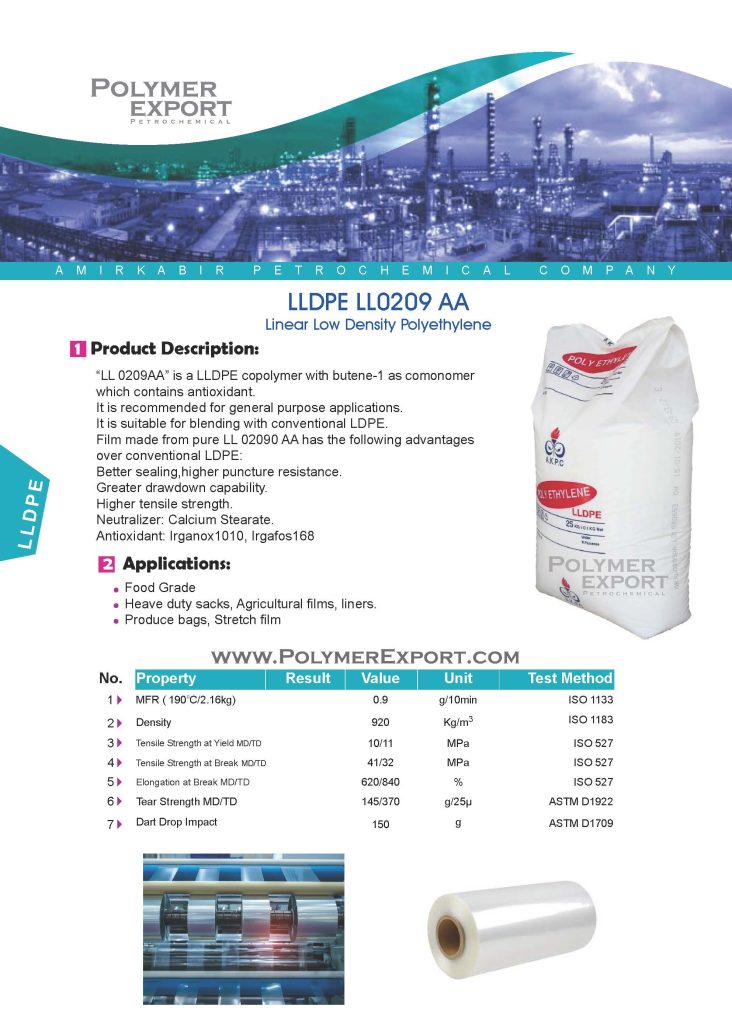

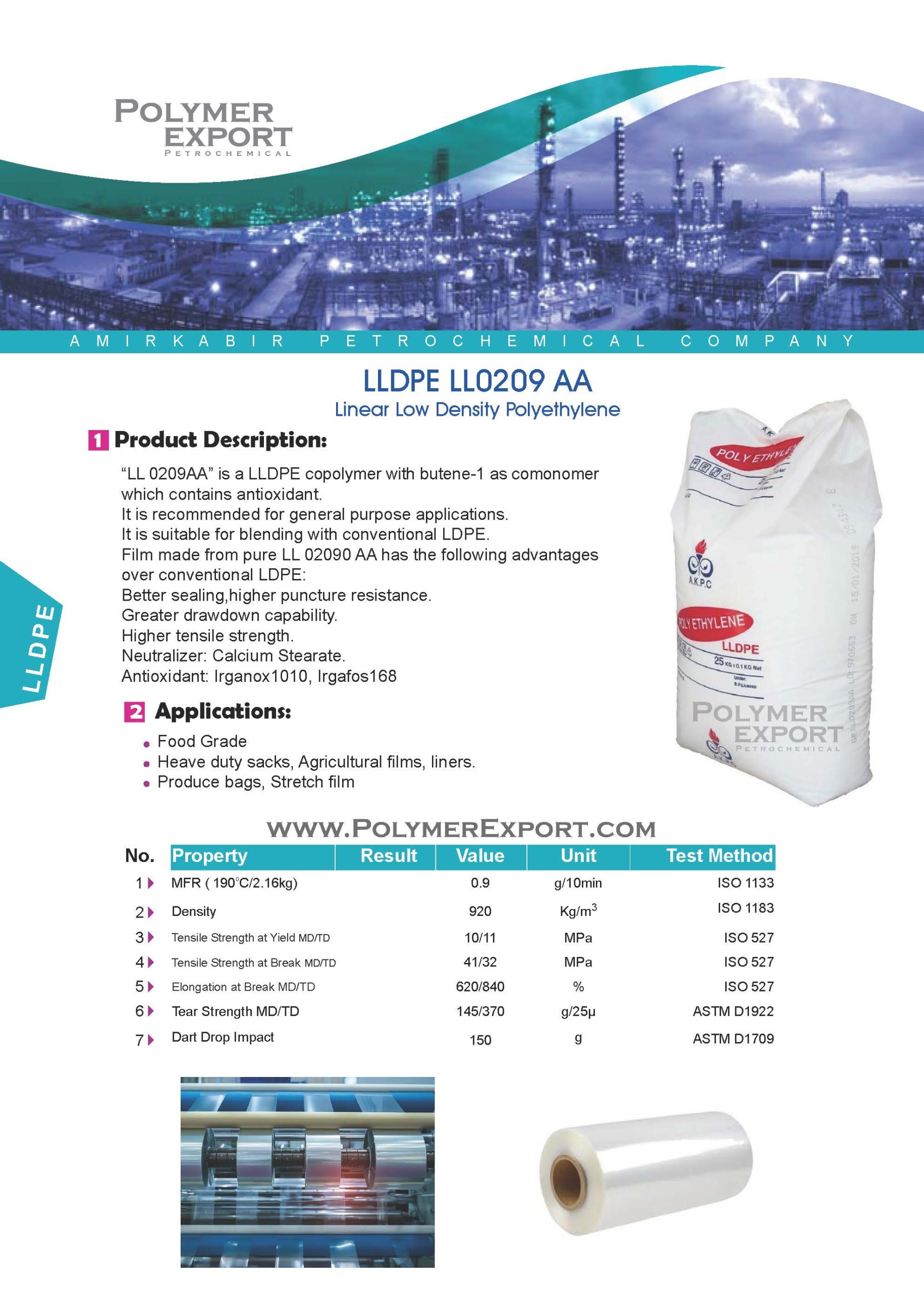

Product Description:

“LL 0209AA” is a LLDPE copolymer with butene-1 as comonomer

which contains antioxidant.

It is recommended for general purpose applications.

It is suitable for blending with conventional LDPE.

Film made from pure LL 02090 AA has the following advantages

over conventional LDPE:

Better sealing,higher puncture resistance.

Greater drawdown capability.

Higher tensile strength.

Neutralizer: Calcium Stearate.

Antioxidant: Irganox1010, Irgafos168

Application:

Food Grade

Heave duty sacks, Agricultural films, liners.

Produce bags, Stretch film

Categories: LLDPE, POLYMERS

Tags: Agricultural films, Heave duty sacks, liners., lldpe 209aa, Produce bags, Stretch film

Description

Additional information

| MFI |

0.9 |

|---|---|

| Density |

0.920 |

Reviews (0)

Be the first to review “LLDPE 209AA AKPC (MFI: 0.9)” Cancel reply

Related products

HDPE 62N07 (Injection)

LDPE 2420H (MFI: 1.9)

Download TDS

Product Description:

Lupolen 2420 H is a non -additivated,low density Polyethylene.It is delivered in

pellet form.

Applications:

Bags & Pouches , Film , Shrink Film , Blown Film , Cast Film

Processing Method: Cast Film , Blown Film

Features: Good Heat Seal, Optical, Good Processability

| MFI |

1.9 |

|---|---|

| Density |

0.924 |

LLDPE 22B02 (MFI: 2)

Download TDS

Typical applications :

For use in lean and rich blend blown film application such as over wrap,

Counter bags, shrink film and boil in the bag applications

Artificial grass

| MFI |

2 |

|---|---|

| Density |

0.920 |

EPS F300

| Bead size - Diamenter |

0.7 – 0.9 mm |

|---|

LDPE 2102 (MFI: 1.9)

Download TDS

Product Description:

LDPE 2102TX00 is low density polyethylene for production of general purpose film.

Applications:

For general purpose film without additives.used in a wide range of widths and thicknesses for pouches ,bags , liners and lamination film.

Additives:

Anti oxidant

| MFI |

1.9 |

|---|---|

| Density |

921 |

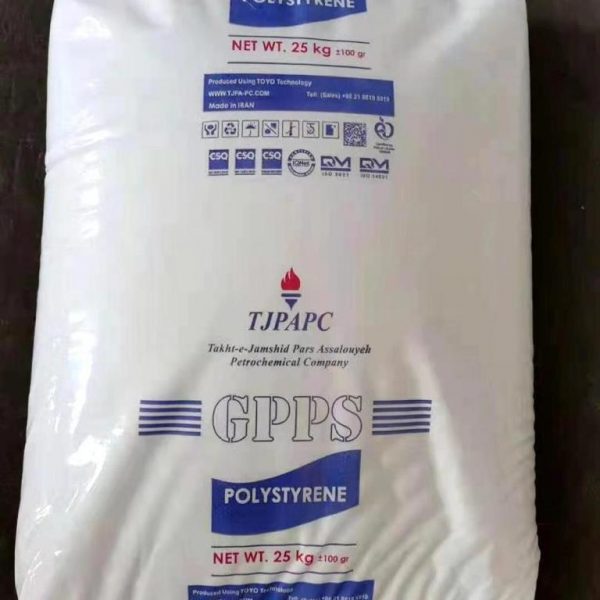

PS GPPS 1551 (MFI: 9)

HDPE 5000s (Monofilament)

Download TDS

Product Description:

HD‐5000S is a HDPE grade

specially designed for monofilament applications, which combines

good processability with high tenacity. This grade has good balance of

mechanical strength and high production rates. HD‐5000S is also well

suited for multiply applications, like ropes and stretched filaments.

Typical Applications :

Fishing net, Rope, Agricultural net, Tarpaulin,

Woven sack.

Characteristic

Properties :

good processability with high

tenacity, good balance of

mechanical strength and high

production rates

Additives :

Antioxidants/Acid scavenger

Antiblock/Processing aid

| MFI |

0.8 |

|---|---|

| Density |

0.954 |

HDPE EX5 (FILM)

| MFI |

0.28 |

|---|

Reviews

There are no reviews yet.