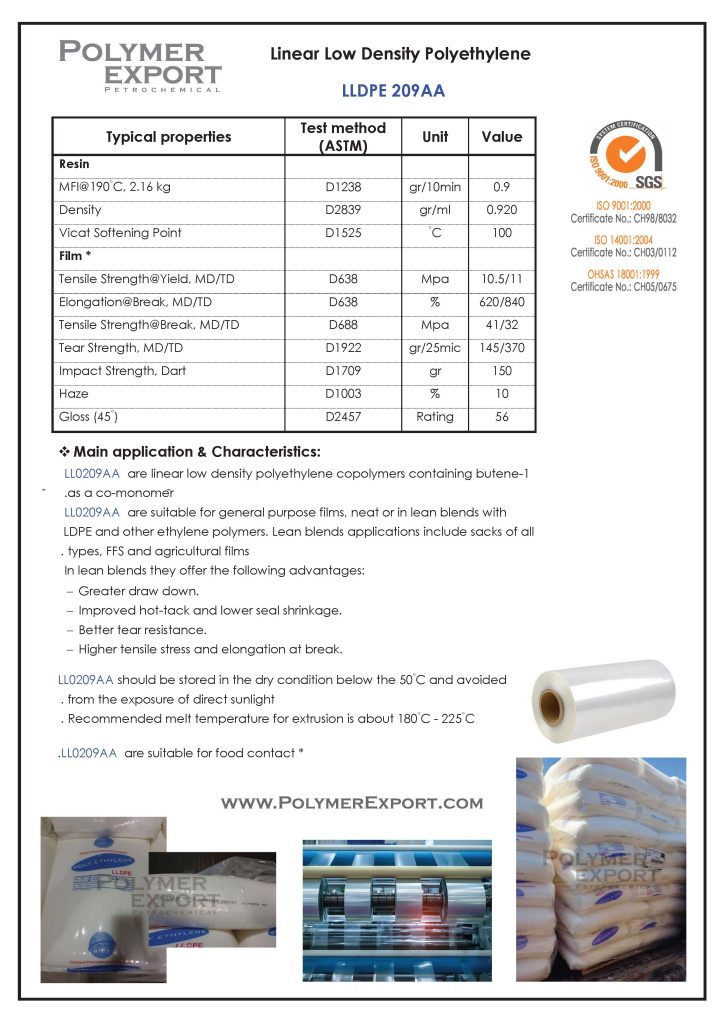

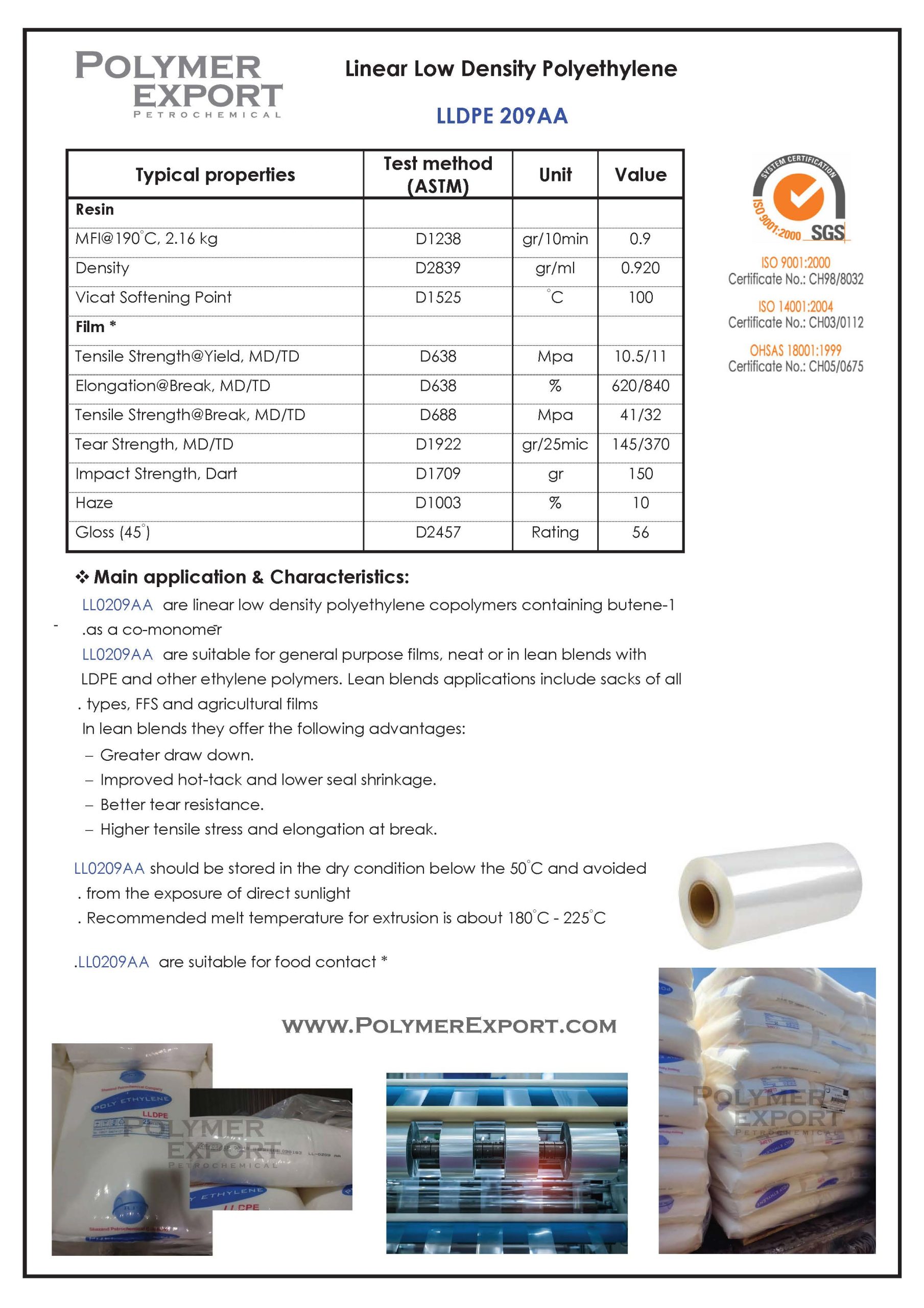

LLDPE 209AA ARAK (MFI: 0.9)

Main application & Characteristics:

LL0209AA are linear low density polyethylene copolymers containing butene-1

.as a co-monomer

LL0209AA are suitable for general purpose films, neat or in lean blends with

LDPE and other ethylene polymers. Lean blends applications include sacks of all

. types, FFS and agricultural films

In lean blends they offer the following advantages:

− Greater draw down.

− Improved hot-tack and lower seal shrinkage.

− Better tear resistance.

− Higher tensile stress and elongation at break.

LL0209AA should be stored in the dry condition below the 50°C and avoided

. from the exposure of direct sunlight

. Recommended melt temperature for extrusion is about 180°C – 225°C

.LL0209AA are suitable for food contact

| MFI |

0.9 |

|---|---|

| Density |

0.920 |

Related products

PS GPPS 1161 (MFI: 4)

SD0150 ABS

| MFI |

1.7 |

|---|

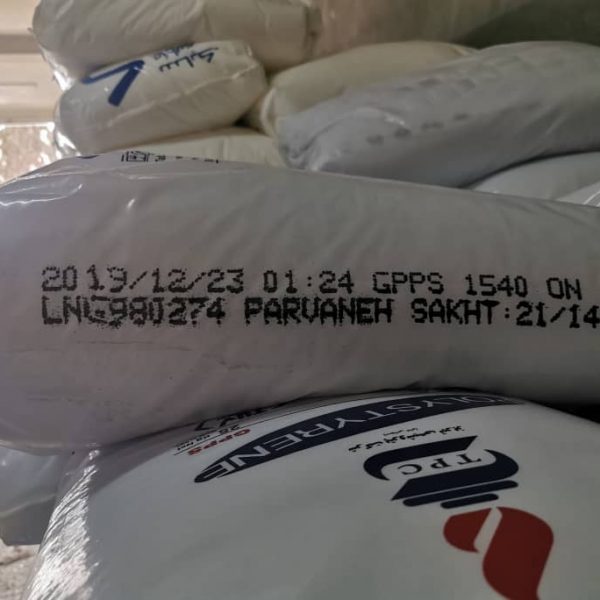

PS GPPS 1540 (MFI: 11)

| MFI |

11 |

|---|

HDPE BL3 JAM (BlowMolding)

| MFI |

23 |

|---|---|

| Density |

0.954 |

HDPE 7000F Mehr ( MHPC )

| MFI |

0.04 |

|---|---|

| Density |

0.954 |

LDPE 2130 (MFI: 0.3)

| MFI |

0.3 |

|---|---|

| Density |

921 |

LDPE 2119 (MFI: 1.9)

| MFI |

1.9 |

|---|

Reviews

There are no reviews yet.