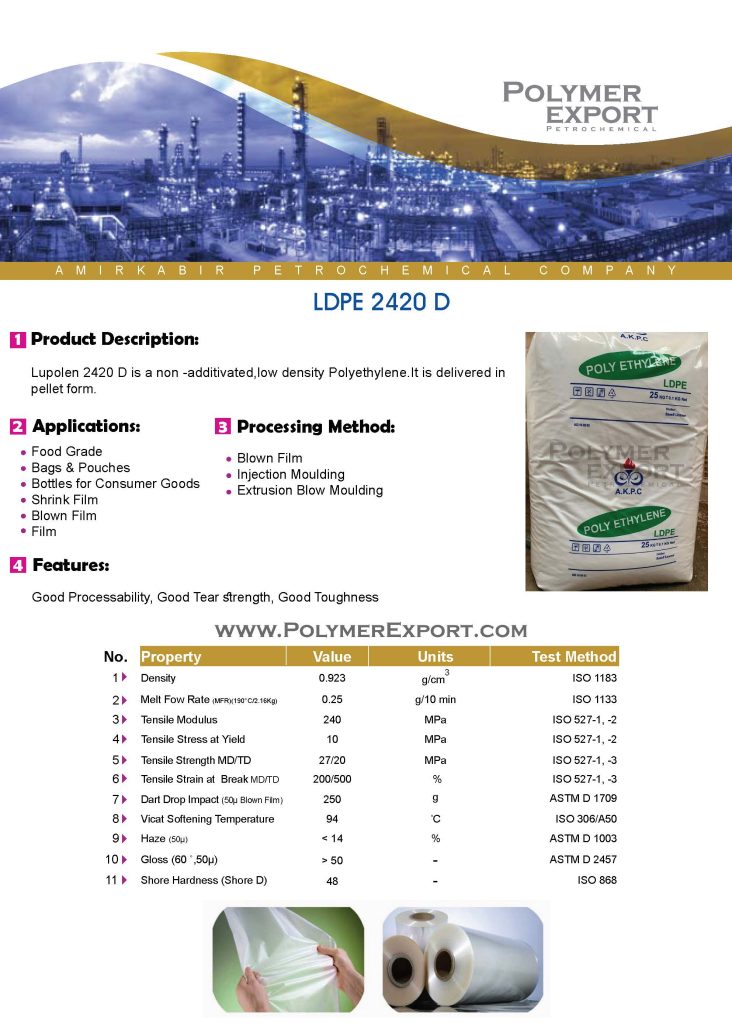

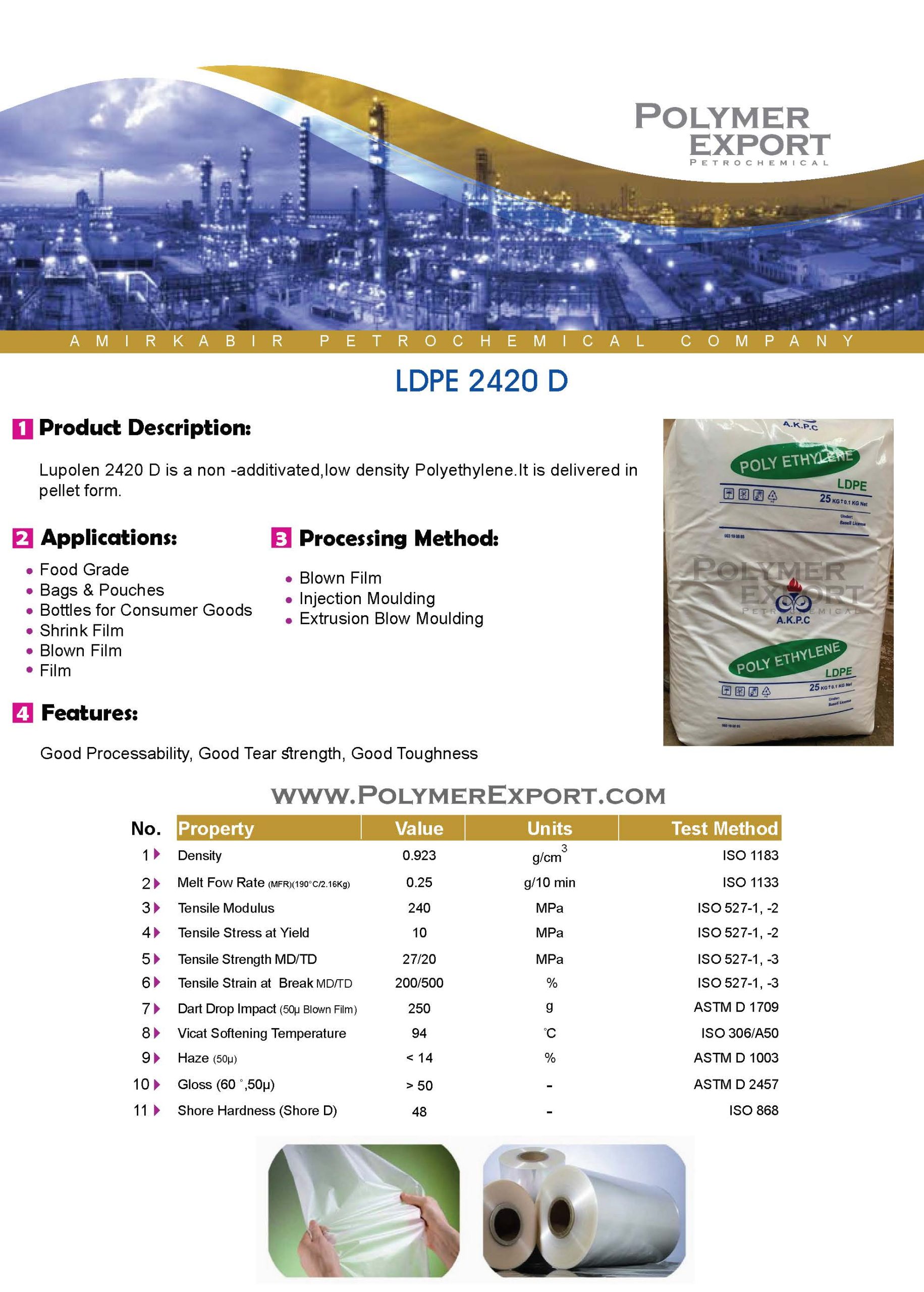

LDPE 2420D (MFI: 0.25)

Download TDS

Product Description:

Lupolen 2420 D is a non -additivated,low density Polyethylene.It is delivered in

pellet form.

Applications:

Food Grade

Bags & Pouches

Bottles for Consumer Goods

Shrink Film

Blown Film

Film

Processing Method:

Blown Film

Injection Moulding

Extrusion Blow Moulding

Features: Good Processability, Good Tear strength, Good Toughness

Categories: LDPE, POLYMERS

Tags: AKPC, AMIR KABIR, BLOWN FILM, LDPE 2420D, Shrink

Description

Additional information

| MFI |

0.25 |

|---|---|

| Density |

0.923 |

Reviews (0)

Be the first to review “LDPE 2420D (MFI: 0.25)” Cancel reply

Related products

HDPE 54B04 (Injection)

LDPE 2100 (MFI: 0.3)

Download TDS

Product Description:

LDPE L2100TN00 is low density polyethylene for production of general purpose film.

Applications:

Grade with excellent toughness and tear strength and outstanding shrink properties.very low energy

consumption during processing and has excellent draw down ability.The material contains no additives and is suitable for application in shrinkhoods,industrial sacks,heavy duty carrier bags and liners Additives: Anti oxidant

consumption during processing and has excellent draw down ability.The material contains no additives and is suitable for application in shrinkhoods,industrial sacks,heavy duty carrier bags and liners Additives: Anti oxidant

| MFI |

0.3 |

|---|---|

| Density |

921 |

PP RP210G (Blow molding)

| MFI |

1.8 |

|---|

PS GPPS 1540 (MFI: 11)

| MFI |

11 |

|---|

Rotational HDPE 3840UA

| MFI |

4 |

|---|

LDPE 2420H (MFI: 1.9)

Download TDS

Product Description:

Lupolen 2420 H is a non -additivated,low density Polyethylene.It is delivered in

pellet form.

Applications:

Bags & Pouches , Film , Shrink Film , Blown Film , Cast Film

Processing Method: Cast Film , Blown Film

Features: Good Heat Seal, Optical, Good Processability

| MFI |

1.9 |

|---|---|

| Density |

0.924 |

HDPE BL3 JAM (BlowMolding)

Download TDS

HF-4760(BL3) is a blow molding grade resin with high density polyethylene with

1-Butene as co monomer which is manufactured by the suspension polymerization

of ethylene monomer. Stiffness, good ESCR are it's spetial properties. High

rigidity and good flowablity which made it proper for usage in bottles and small

blow molding goods.

Applications

Small blow moulding

Bottles

Containers (up to 5 lit )

Packing of pharmaceuticals & surfactants

Additives:

• Antioxidant/Process stabilizer

• Lubricant/ acid scavenger

Features:

• High density and Stiffness, good

flowabilitty and impact Stvength

and good Stvess Cvacking resistance.

| MFI |

23 |

|---|---|

| Density |

0.954 |

LLDPE 22B02 (MFI: 2)

Download TDS

Typical applications :

For use in lean and rich blend blown film application such as over wrap,

Counter bags, shrink film and boil in the bag applications

Artificial grass

| MFI |

2 |

|---|---|

| Density |

0.920 |

Reviews

There are no reviews yet.