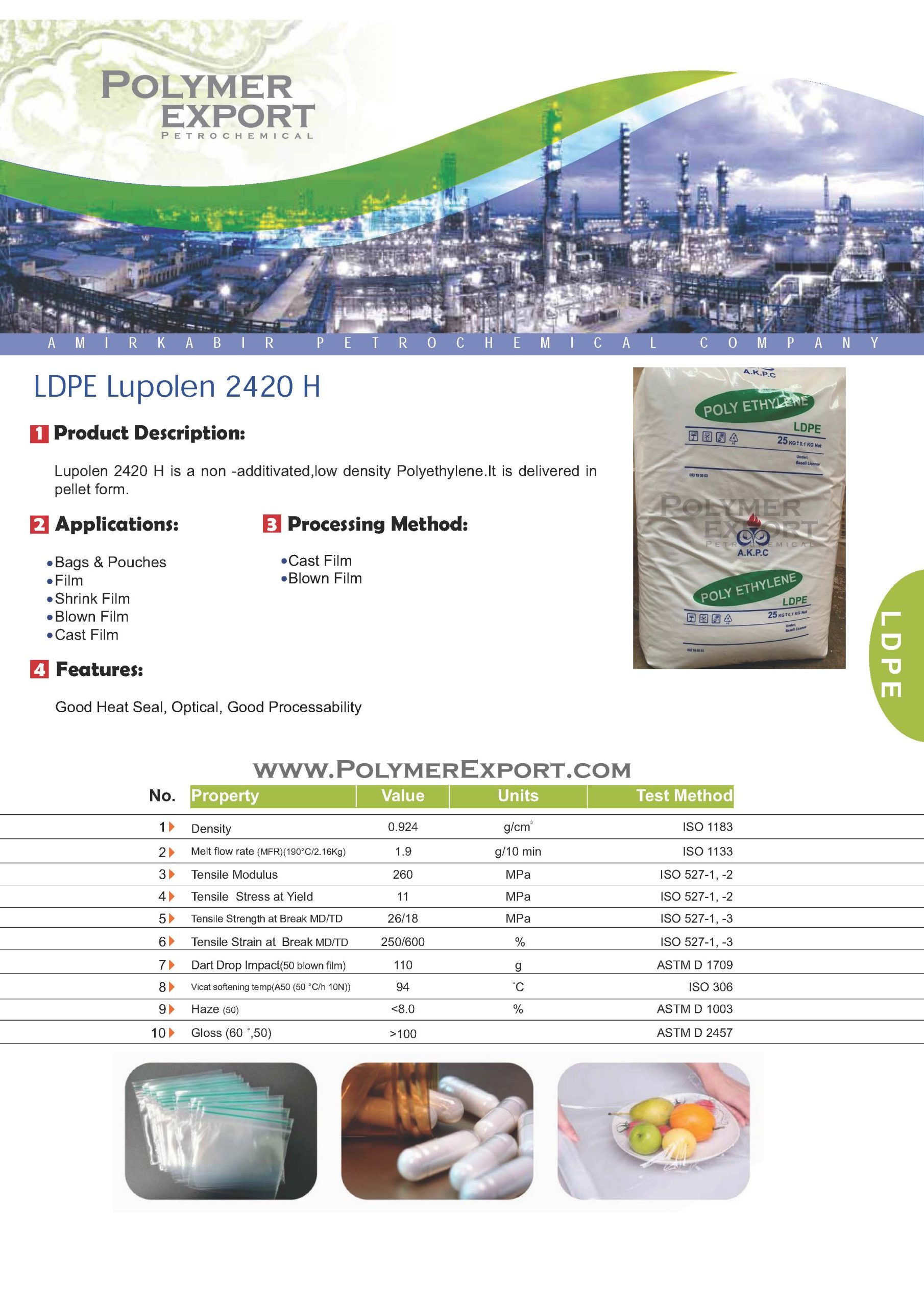

LDPE 2420H (MFI: 1.9)

Download TDS

Product Description:

Lupolen 2420 H is a non -additivated,low density Polyethylene.It is delivered in

pellet form.

Applications:

Bags & Pouches , Film , Shrink Film , Blown Film , Cast Film

Processing Method: Cast Film , Blown Film

Features: Good Heat Seal, Optical, Good Processability

Categories: LDPE, POLYMERS

Tags: AKPC, AMIR KABIR, Bags & Pouches, BLOWN FILM, LDPE 2420H, Shrink Film

Related products

LDPE 2130 (MFI: 0.3)

Download TDS

Product Description:

LFI2130 is a high molecular weight, low density polyethylene for producing heavy-duty packaging films for applications like shrink hoods. It contains no slip agent and antiblock additives. It gives outstanding strength and toughness, draw down ability and very good biaxial shrink properties. LFI2130 has been manufactured under SABTEC licensed technology.

Applications:

Blown film extrusion, heavy duty packaging film, shrink hoods, industrial sacks, carrier bag and liners.

Status: Commercial: Active

Form(s): Pellet

Attribute:

Good strenght and toughness, very good melt strength.

Additives:

Antioxidant: Yes

Antiblock : No

Slip Agent : No

| MFI |

0.3 |

|---|---|

| Density |

921 |

HDPE EX5 (FILM)

| MFI |

0.28 |

|---|

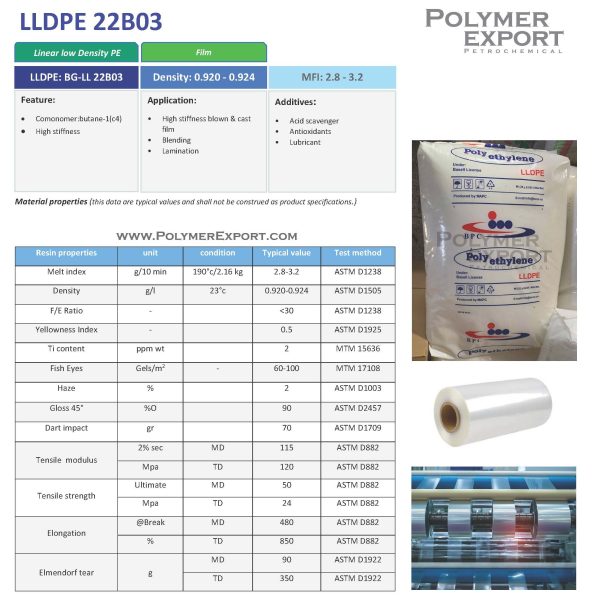

LLDPE 22B03 (MFI: 3)

Download TDS

Application:

• High stiffness blown & cast

film

• Blending

• Lamination

Feature:

Co monomer:butane-1(c4)

High stiffness

Additives:

• Acid scavenger

• Antioxidants

• Lubricant

| MFI |

3 |

|---|---|

| Density |

0.920 |

PS GPPS 1540 (MFI: 11)

| MFI |

11 |

|---|

HDPE 7000F Mehr ( MHPC )

Download TDS

Granules 7000 F is a high density polyethylene resin ;a product of bi-modal process from Mitsui Chemicals, Inc. of Japan

APPLICATION:

shooing bag and T-shirt bag

garbage bag

liner bag

enhanced ultra thin film

high stiffness

wide service temperature range, UV resistance

recommend film thickness at 10-20 micron

high tensile strength with good dart impact strength

low gel content

good moisture barrier

food contact applicable

good impact resistance and processability

Packing & Loading:

Each truck 22mt or 24.75mt

1375kg each pallet

پلی اتیلن سنگین گرید فیلم

پتروشیمی مهرعسلویه پلاستیک دانه نایلون دسته دار فروشگاهی

| MFI |

0.04 |

|---|---|

| Density |

0.954 |

HDPE CRP100N (PIPE)

Download TDS

HM-CRP100N (PE100) is a natural pipe grade resin which

is manufactured by suspension polymerization of ethylen

monomer, HM-CRP100N )PE100) is a bi-model high density

polyethylene with 1-Butene as co monomer.

Main Applications

• Top quality PE100 pressure

• Pipes for gas and water

transportaion at higher pressures

or with thinner walls as PE80 (UV

stabilization and/ or pigments during

precessing)

Characteristic

Properties

• Natural PE100 pipe resin.

Additives

• Antioxidant/Process stabilizer

• Lubricant (processing aid)/ acid

scavenger

| MFI |

0.22 |

|---|

PP 1102XK (Raffia)

| MFI |

4 |

|---|

HDPE 5000s (Monofilament)

Download TDS

Product Description:

HD‐5000S is a HDPE grade

specially designed for monofilament applications, which combines

good processability with high tenacity. This grade has good balance of

mechanical strength and high production rates. HD‐5000S is also well

suited for multiply applications, like ropes and stretched filaments.

Typical Applications :

Fishing net, Rope, Agricultural net, Tarpaulin,

Woven sack.

Characteristic

Properties :

good processability with high

tenacity, good balance of

mechanical strength and high

production rates

Additives :

Antioxidants/Acid scavenger

Antiblock/Processing aid

| MFI |

0.8 |

|---|---|

| Density |

0.954 |