LDPE 2125A (MFI: 2.5)

Product Description

LFI2125A is a low density polyethylene, with a medium level of anti-block and slip agent (Erucamide). This grade offers good optical properties, low energy consumption during processing, adequate COF level and excellent draw down. LFI2125A has been manufactured under SABTEC licensed technology.

Applications:

Blown film extrusion, packaging film for food and goods, general lamination film.

Status: Commercial: Active

Form(s): Pellet

Attribute:

Good toughness, high speed converting without sticking, good optical properties, suitable when ultimate down gauging is required.

Additives:

Antioxidant: Yes

Antiblock : Yes

Slip Agent : Yes

| MFI |

2.5 |

|---|---|

| Density |

921 |

Related products

HDPE 54B04 (Injection)

LLDPE 22B02 (MFI: 2)

| MFI |

2 |

|---|---|

| Density |

0.920 |

PS GPPS 1161 (MFI: 4)

LLDPE 209AA ARAK (MFI: 0.9)

| MFI |

0.9 |

|---|---|

| Density |

0.920 |

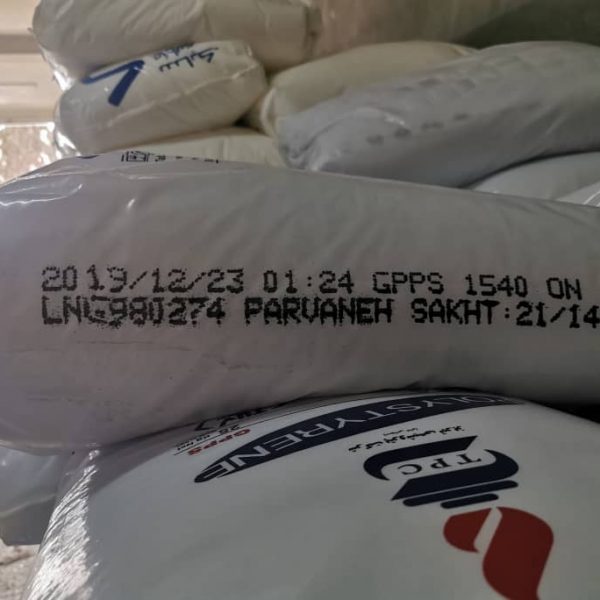

PS GPPS 1540 (MFI: 11)

| MFI |

11 |

|---|

PP 1104K (OPP)

| MFI |

3.2 |

|---|

HDPE 62N07 (Injection)

HDPE 7000F Mehr ( MHPC )

| MFI |

0.04 |

|---|---|

| Density |

0.954 |

Reviews

There are no reviews yet.