LDPE 2102 (MFI: 1.9)

Product Description:

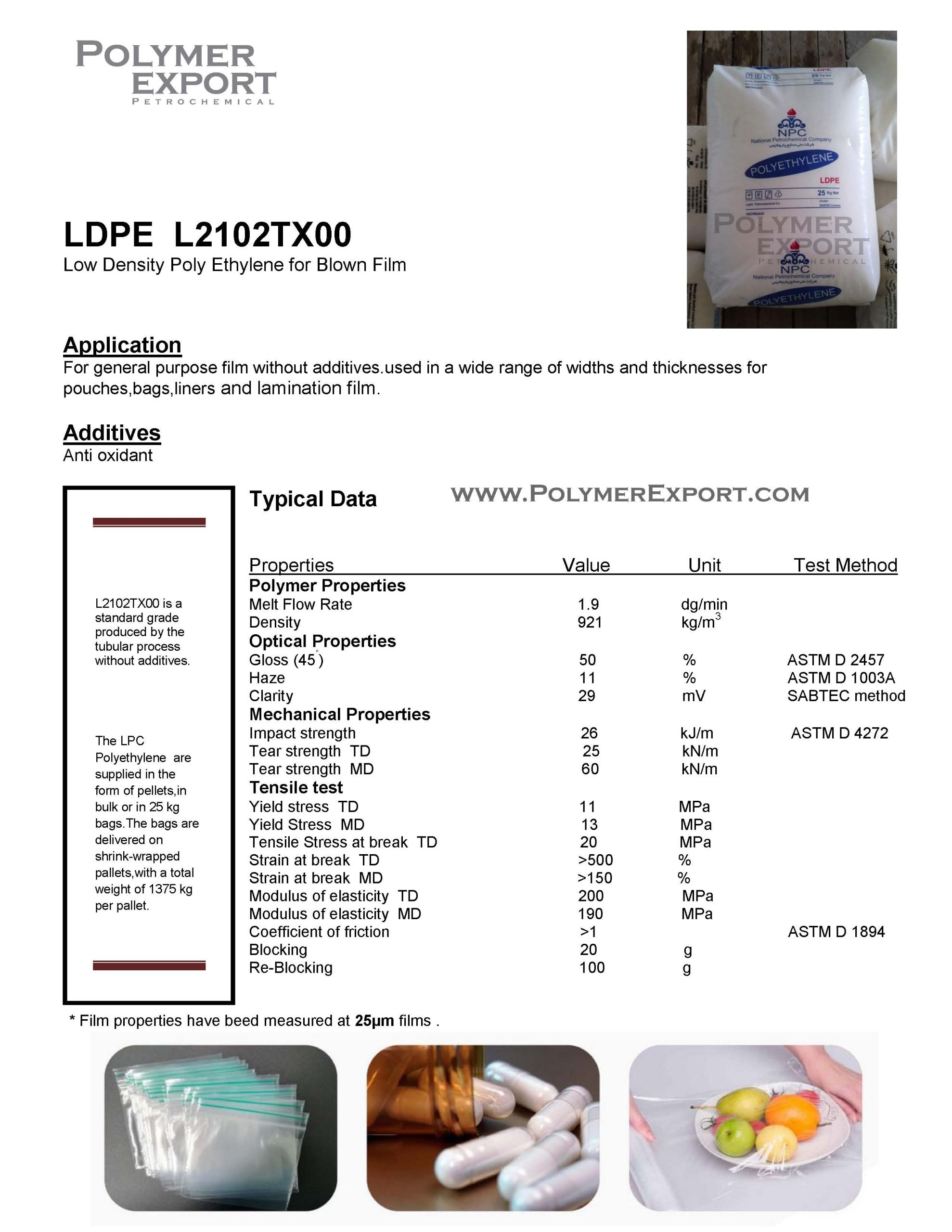

LDPE 2102TX00 is low density polyethylene for production of general purpose film.

Applications:

For general purpose film without additives.used in a wide range of widths and thicknesses for pouches ,bags , liners and lamination film.

Additives:

Anti oxidant

Description

Additional information

| MFI |

1.9 |

|---|---|

| Density |

921 |

Reviews (0)

Be the first to review “LDPE 2102 (MFI: 1.9)” Cancel reply

Related products

LDPE 2420D (MFI: 0.25)

Download TDS

Product Description:

Lupolen 2420 D is a non -additivated,low density Polyethylene.It is delivered in

pellet form.

Applications:

Food Grade

Bags & Pouches

Bottles for Consumer Goods

Shrink Film

Blown Film

Film

Processing Method:

Blown Film

Injection Moulding

Extrusion Blow Moulding

Features: Good Processability, Good Tear strength, Good Toughness

| MFI |

0.25 |

|---|---|

| Density |

0.923 |

HDPE 62N07 (Injection)

PP RP210G (Blow molding)

| MFI |

1.8 |

|---|

LLDPE 22B02 (MFI: 2)

Download TDS

Typical applications :

For use in lean and rich blend blown film application such as over wrap,

Counter bags, shrink film and boil in the bag applications

Artificial grass

| MFI |

2 |

|---|---|

| Density |

0.920 |

HDPE BL3 JAM (BlowMolding)

Download TDS

HF-4760(BL3) is a blow molding grade resin with high density polyethylene with

1-Butene as co monomer which is manufactured by the suspension polymerization

of ethylene monomer. Stiffness, good ESCR are it's spetial properties. High

rigidity and good flowablity which made it proper for usage in bottles and small

blow molding goods.

Applications

Small blow moulding

Bottles

Containers (up to 5 lit )

Packing of pharmaceuticals & surfactants

Additives:

• Antioxidant/Process stabilizer

• Lubricant/ acid scavenger

Features:

• High density and Stiffness, good

flowabilitty and impact Stvength

and good Stvess Cvacking resistance.

| MFI |

23 |

|---|---|

| Density |

0.954 |

PP 1104K (OPP)

| MFI |

3.2 |

|---|

HDPE 52518 (Injection)

Download TDS

HD-52518 is a HDPE copolymer which manufactured by gas phase process. This grade is LLDPE Injection Moulding, Extrusion Coating & Rotomoulding. Injection molding for application requiring a good balance between easy of processability and flowability and mechanical properties are the special perpuse of this grade.

Features

• Good balance between easy of

processability and flowability

Applications

• Housewares

High fluidity

Additives

• Thermal Antioxidant

| MFI |

18 |

|---|---|

| Density |

0.952 |

Reviews

There are no reviews yet.