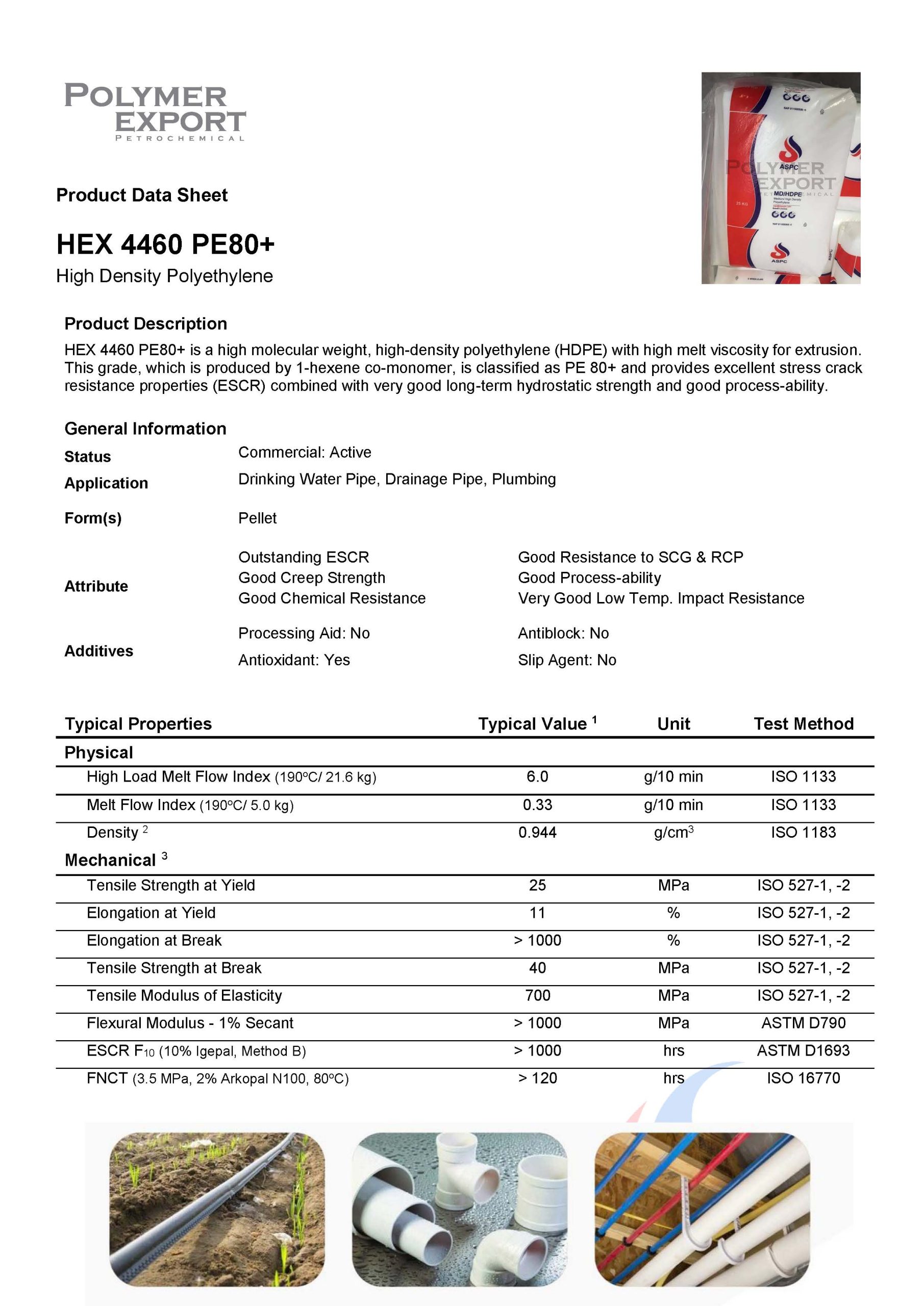

HEX 4460 PE80+

Product Description:

HEX 4460 PE80+ is a high molecular weight, high-density polyethylene (HDPE) with high melt viscosity for extrusion. This grade, which is produced by 1-hexene co-monomer, is classified as PE 80+ and provides excellent stress crack resistance properties (ESCR) combined with very good long-term hydrostatic strength and good process-ability.

Application

Drinking Water Pipe, Drainage Pipe, Plumbing

Form(s)

Pellet

Attribute

Outstanding ESCR

Good Resistance to SCG & RCP

Good Creep Strength

Good Process-ability

Good Chemical Resistance

Very Good Low Temp. Impact Resistance

Additives

Processing Aid: No

Antioxidant: Yes

Antiblock: No

Slip Agent: No

| MFI |

0.33 |

|---|

Related products

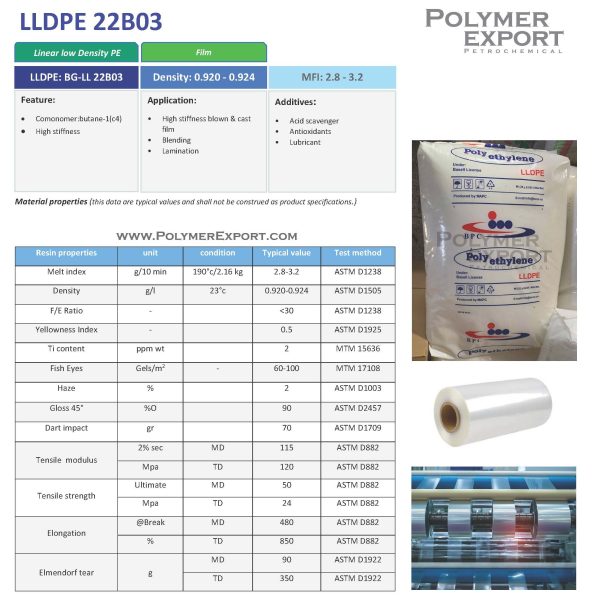

LLDPE 22B03 (MFI: 3)

| MFI |

3 |

|---|---|

| Density |

0.920 |

PP 552R (Fiber)

| MFI |

25 |

|---|

LLDPE 22B02 (MFI: 2)

| MFI |

2 |

|---|---|

| Density |

0.920 |

PP 1102XL (Extrusion)

| MFI |

5.5 |

|---|

EPS F300

| Bead size - Diamenter |

0.7 – 0.9 mm |

|---|

LDPE 2130 (MFI: 0.3)

| MFI |

0.3 |

|---|---|

| Density |

921 |

HDPE 52518 (Injection)

| MFI |

18 |

|---|---|

| Density |

0.952 |

HDPE 5000s (Monofilament)

| MFI |

0.8 |

|---|---|

| Density |

0.954 |

Reviews

There are no reviews yet.