Handellling and Health Safty

sMolten polymers could be injured skin or eye so safty glasses

and appropriate gloves are suggested to prevent possible

thermal injuries. Also appropriate ventilation is suggested in

working by melt polymer.

Accumulation of fines or dust particles that are in this grade

is not suitable because of explosion hazard probability. So

adequated filters and grounding exists at all time are recommended.Storage

Polyethylen products (in pelletised or powder form) should

not be stored in direct sunshine and/or heat radiation.

Ultraviolet cause a change in the material properties.The

Storage area should be dry and preferably don’t exceed 50

°C. Under cool, dry, dark conditions Jam Polymers polyolefin

resins are expected to maintain the original material and

processing properties for at least 18 month. . JPC would not

ressponsible about quality diminishing such as color change,

bad smell or ets which caused by bad storage conditions. It

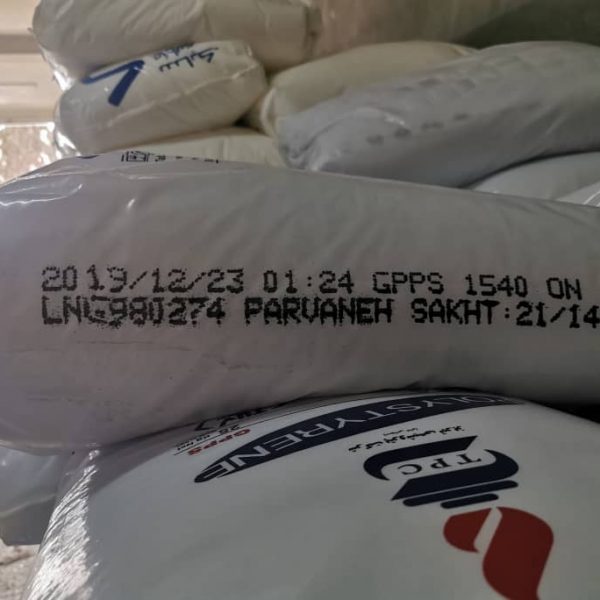

is better to process PE resin within 6 months after delivery.pakaging

Jam Polymers Polyolefin resins are supplied in pllet form

packed in 25kg bags. Alternative packaging modes are avalable

for selected grades.

Reviews

There are no reviews yet.