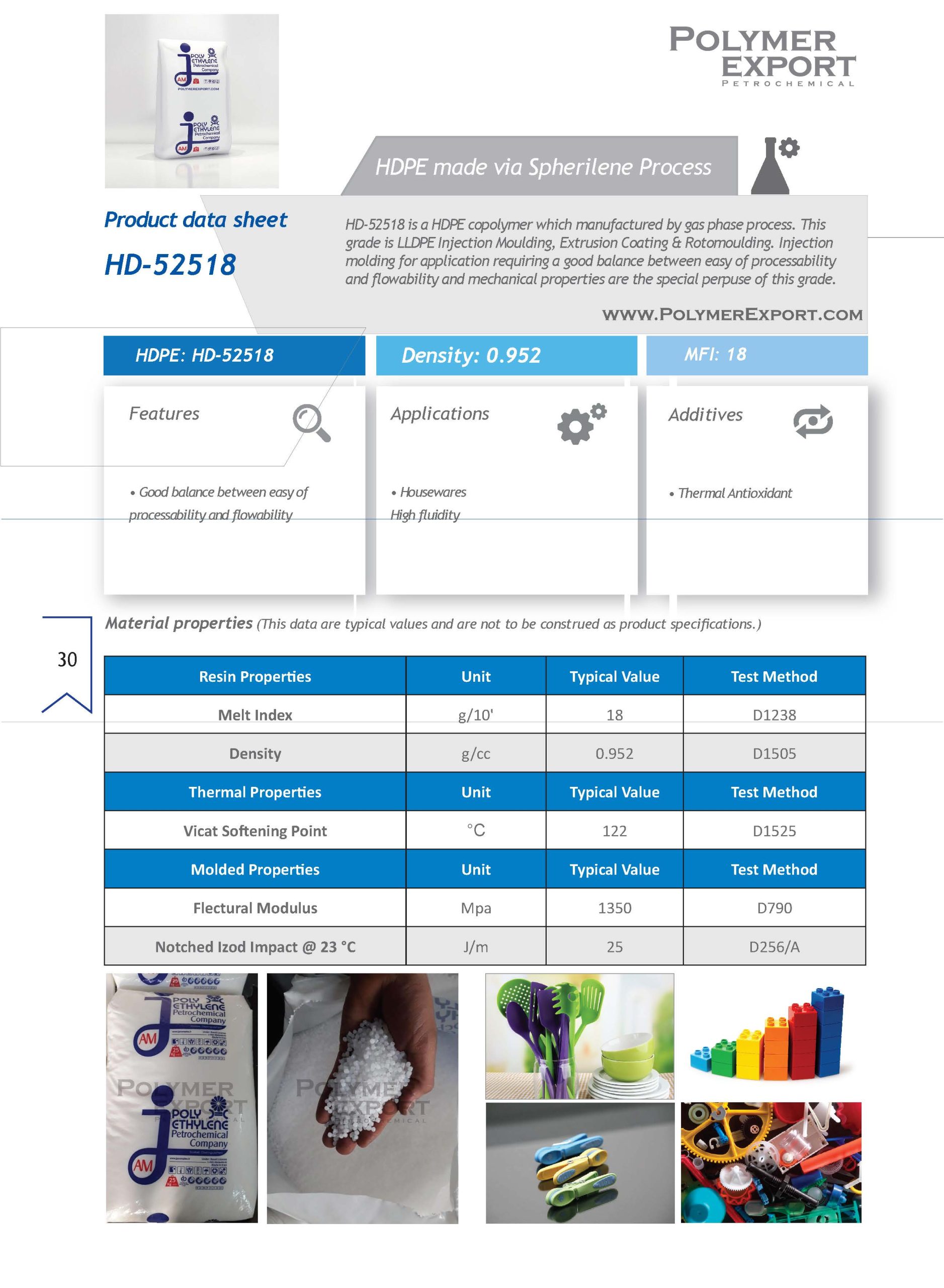

HDPE 52518 (Injection)

HD-52518 is a HDPE copolymer which manufactured by gas phase process. This grade is LLDPE Injection Moulding, Extrusion Coating & Rotomoulding. Injection molding for application requiring a good balance between easy of processability and flowability and mechanical properties are the special perpuse of this grade.

Features

• Good balance between easy of

processability and flowability

Applications

• Housewares

High fluidity

Additives

• Thermal Antioxidant

Categories: HDPE, POLYMERS

Tags: 52B18, Extrusion Coating, HDPE 52518, Injection, JAM

Related products

LDPE 2420H (MFI: 1.9)

Download TDS

Product Description:

Lupolen 2420 H is a non -additivated,low density Polyethylene.It is delivered in

pellet form.

Applications:

Bags & Pouches , Film , Shrink Film , Blown Film , Cast Film

Processing Method: Cast Film , Blown Film

Features: Good Heat Seal, Optical, Good Processability

| MFI |

1.9 |

|---|---|

| Density |

0.924 |

HDPE 62N07 (Injection)

SD0150 ABS

| MFI |

1.7 |

|---|

HDPE CRP100N (PIPE)

Download TDS

HM-CRP100N (PE100) is a natural pipe grade resin which

is manufactured by suspension polymerization of ethylen

monomer, HM-CRP100N )PE100) is a bi-model high density

polyethylene with 1-Butene as co monomer.

Main Applications

• Top quality PE100 pressure

• Pipes for gas and water

transportaion at higher pressures

or with thinner walls as PE80 (UV

stabilization and/ or pigments during

precessing)

Characteristic

Properties

• Natural PE100 pipe resin.

Additives

• Antioxidant/Process stabilizer

• Lubricant (processing aid)/ acid

scavenger

| MFI |

0.22 |

|---|

PP 3212E (PIPE)

| MFI |

0.25 |

|---|

LDPE 2420D (MFI: 0.25)

Download TDS

Product Description:

Lupolen 2420 D is a non -additivated,low density Polyethylene.It is delivered in

pellet form.

Applications:

Food Grade

Bags & Pouches

Bottles for Consumer Goods

Shrink Film

Blown Film

Film

Processing Method:

Blown Film

Injection Moulding

Extrusion Blow Moulding

Features: Good Processability, Good Tear strength, Good Toughness

| MFI |

0.25 |

|---|---|

| Density |

0.923 |

HDPE 5000s (Monofilament)

Download TDS

Product Description:

HD‐5000S is a HDPE grade

specially designed for monofilament applications, which combines

good processability with high tenacity. This grade has good balance of

mechanical strength and high production rates. HD‐5000S is also well

suited for multiply applications, like ropes and stretched filaments.

Typical Applications :

Fishing net, Rope, Agricultural net, Tarpaulin,

Woven sack.

Characteristic

Properties :

good processability with high

tenacity, good balance of

mechanical strength and high

production rates

Additives :

Antioxidants/Acid scavenger

Antiblock/Processing aid

| MFI |

0.8 |

|---|---|

| Density |

0.954 |

PP 1102XL (Extrusion)

| MFI |

5.5 |

|---|