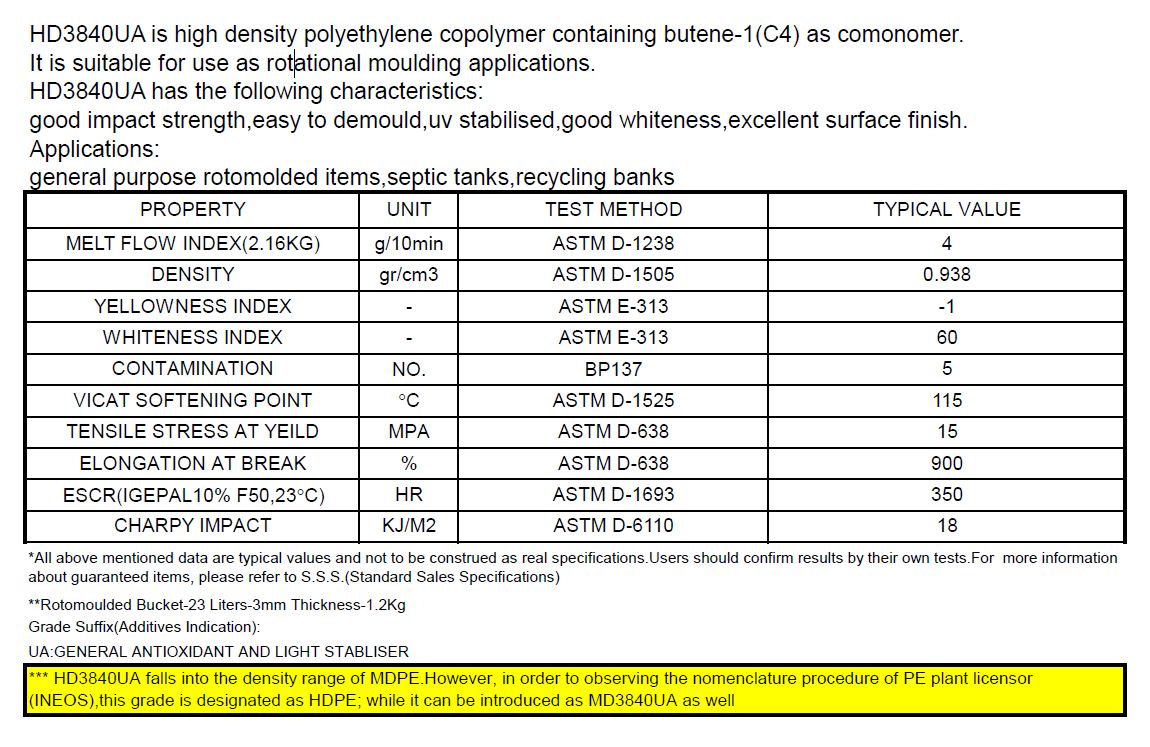

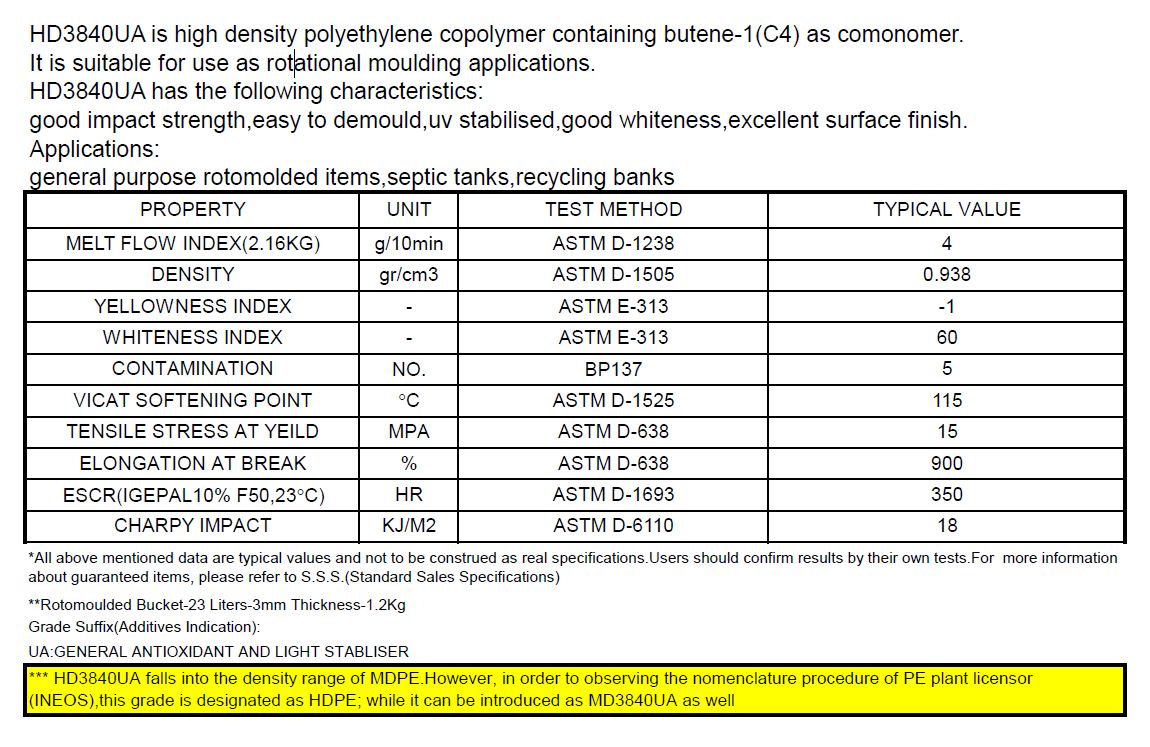

HD3840UA has the following characteristics:

good impact strength,easy to demould,uv stabilised,good whiteness,excellent surface finish.Applications:

general purpose rotomolded items,septic tanks,recycling banks.

4

MFI

HD3840UA (Rotational Moulding)

Product Description:

HD3840UA is a linear, UV stabilized virgin medium density polyethylene

copolymer grade (MDPE), with a narrow molecular weight distribution.

HD3840UA is high density polyethylene copolymer containing butene-1(C4) as comonomer. It is suitable for use as rotational moulding applications.

Characteristics:

− High stiffness.

− Good impact stress.

− Whiteness.

− UV stabilized.

− Good Stress Cracking Resistance.

− Excellent process-ability.

− Excellent internal and external surface finish.

Typical applications are:

− Rotational moulded items with good stiffness, such as: Septic tanks and

Ordinary containers.

− Injection moulded technical parts and closure

HD3840UA is suitable for food contact.

HD3840UA has the following characteristics:

good impact strength,easy to demould,uv stabilised,good whiteness,excellent surface finish.Applications:

general purpose rotomolded items,septic tanks,recycling banks.

| MFI |

4 |

|---|

| MFI |

1.8 |

|---|

| MFI |

1.9 |

|---|

| MFI |

0.3 |

|---|---|

| Density |

921 |

| MFI |

5.5 |

|---|

| MFI |

0.04 |

|---|---|

| Density |

0.954 |

| MFI |

18 |

|---|---|

| Density |

0.952 |

| MFI |

0.22 |

|---|

Reviews

There are no reviews yet.