• Density: 1.04gr/cm3 (app.)

• Approximate shrinkage in mould: 0.4-0.7% (ASTM D 955)

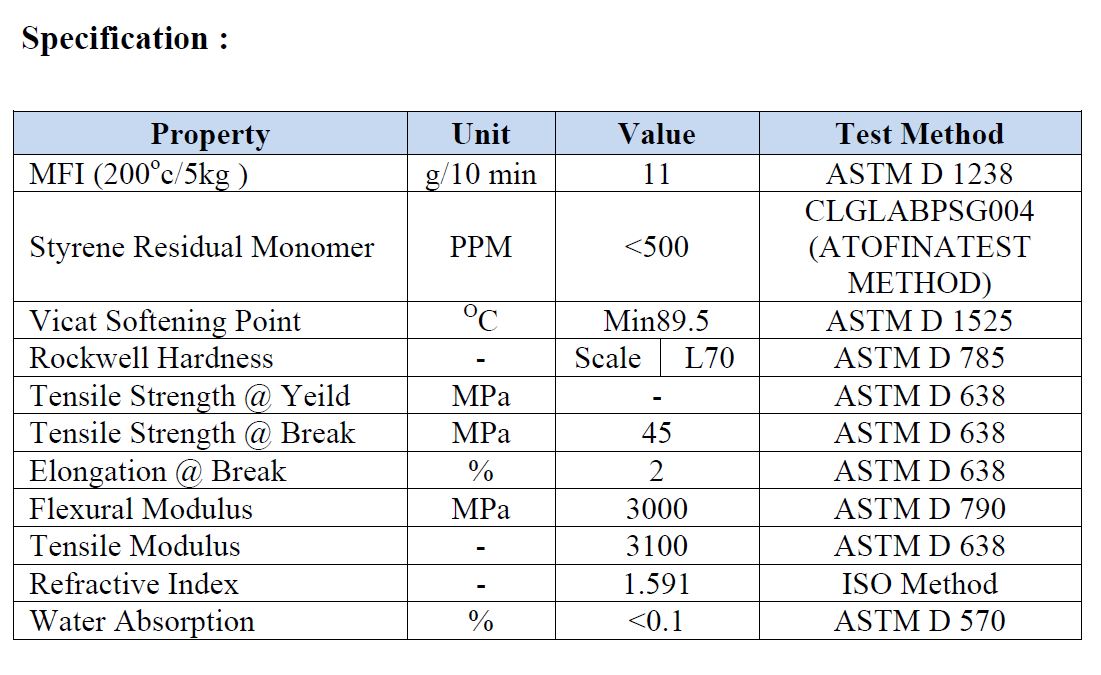

• All tests are carried out at 23OC unless otherwise stated.

• The above data are typical laboratory average, intended to

serve as guides only.Food Contact Properties :

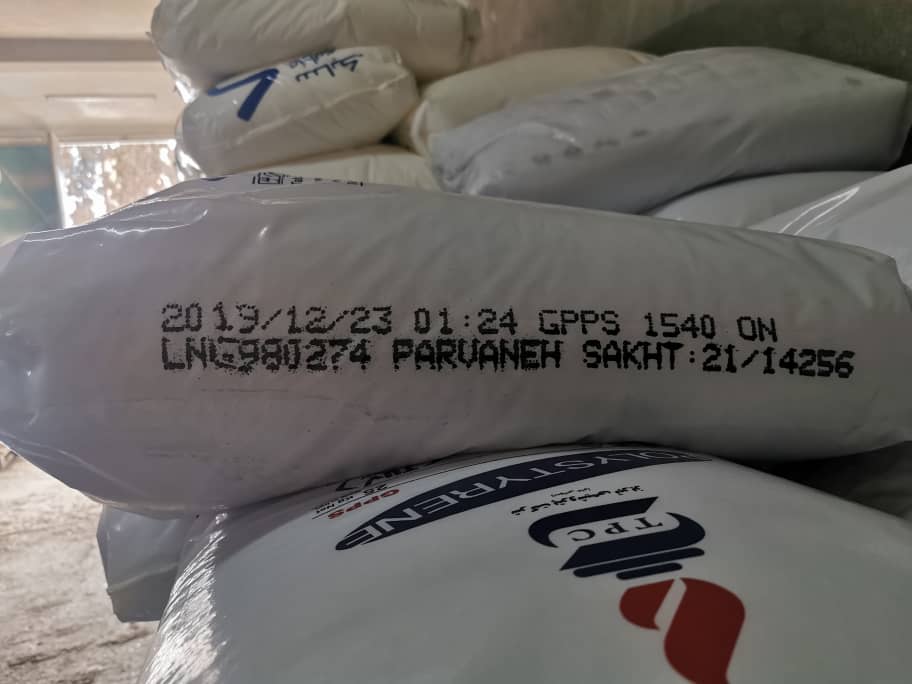

GPPS 1540 is a food contact grade, unless the term “Non-Food

Contact” is printed on the bags.

Reviews

There are no reviews yet.