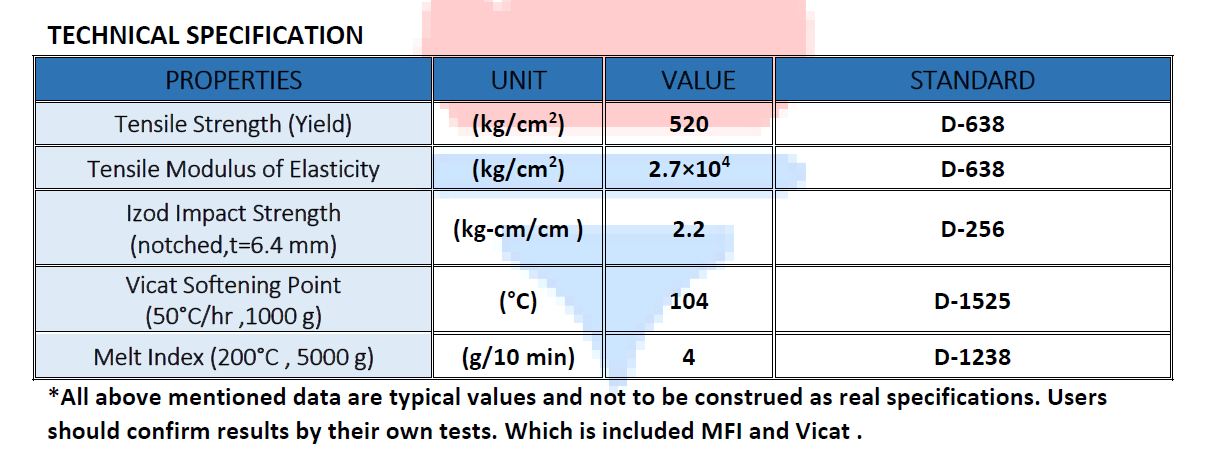

PS GPPS 1161 (MFI: 4)

General Purpose Polystyrene

This grade is high heat for PS foam.

Main Applications:

Parts for home electrical appliances (nameplates, transparent display covers for VTR, etc), Office stationary, Foamed PS, etc

Categories: GPPS , HIPS , EPS , ABS, POLYMERS

Tags: 1161, GPPS, POLYMER EXPORT, TJPAPC

Description

Additional information

| MFI |

4 |

|---|

Reviews (0)

Be the first to review “PS GPPS 1161 (MFI: 4)” Cancel reply

Related products

PP 1104K (OPP)

| MFI |

3.2 |

|---|

HDPE 52518 (Injection)

Download TDS

HD-52518 is a HDPE copolymer which manufactured by gas phase process. This grade is LLDPE Injection Moulding, Extrusion Coating & Rotomoulding. Injection molding for application requiring a good balance between easy of processability and flowability and mechanical properties are the special perpuse of this grade.

Features

• Good balance between easy of

processability and flowability

Applications

• Housewares

High fluidity

Additives

• Thermal Antioxidant

| MFI |

18 |

|---|---|

| Density |

0.952 |

HDPE EX5 (FILM)

| MFI |

0.28 |

|---|

EPS F300

| Bead size - Diamenter |

0.7 – 0.9 mm |

|---|

LDPE 2420D (MFI: 0.25)

Download TDS

Product Description:

Lupolen 2420 D is a non -additivated,low density Polyethylene.It is delivered in

pellet form.

Applications:

Food Grade

Bags & Pouches

Bottles for Consumer Goods

Shrink Film

Blown Film

Film

Processing Method:

Blown Film

Injection Moulding

Extrusion Blow Moulding

Features: Good Processability, Good Tear strength, Good Toughness

| MFI |

0.25 |

|---|---|

| Density |

0.923 |

PP 552R (Fiber)

| MFI |

25 |

|---|

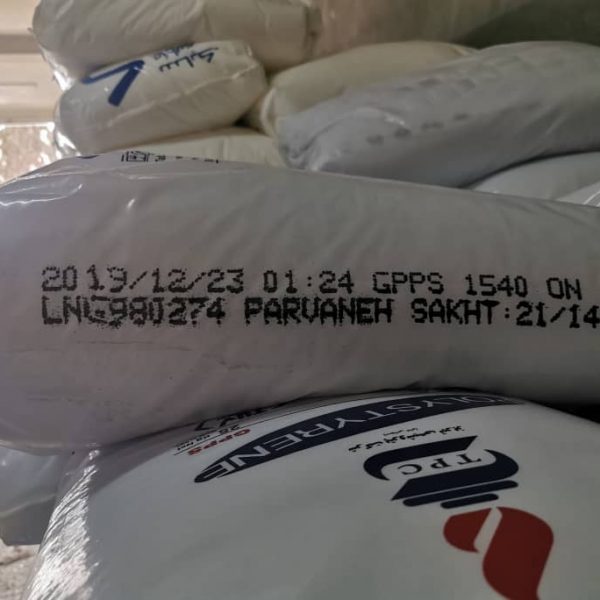

PS GPPS 1540 (MFI: 11)

| MFI |

11 |

|---|

LDPE 2119 (MFI: 1.9)

Download TDS

Product Description:

LFI2119 is a low-density polyethylene, with excellent optical properties. This grade offers high output and excellent drawdown and specially designed for general-purpose thin films. LFI2119 has been manufactured under SABTEC licensed technology.

Applications:

Blown film extrusion, packaging film, general lamination film

Status: Commercial: Active

Form(s): Pellet

Attribute:

Very good optical properties, good toughness, good melt strength

Additives:

Antioxidant: Yes

Antiblock : No

Slip Agent : No

| MFI |

1.9 |

|---|

Reviews

There are no reviews yet.