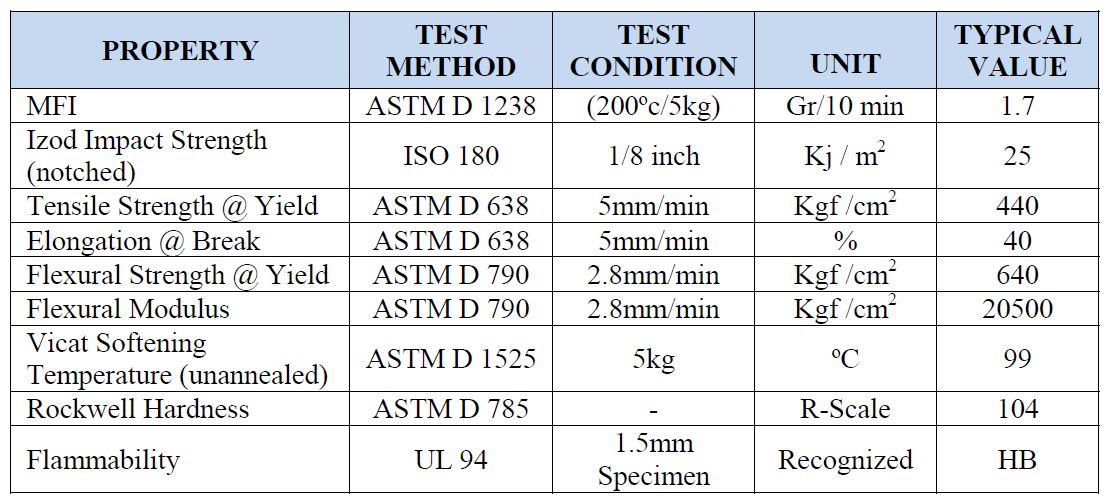

Typical Data :

Density of this grade is approximately1.04 gr/cm3.

Shrinkage of all ABS grades in mold is approximately 0.3 % ~ 0.6 %

(ASTM D 955).

All tests are carried out at 23 ºC unless otherwise stated.

The above data are typical laboratory average. They are intended to

serve as guide only.

Processing Condition :

SD-0150 ABS granules absorbs moisture from atmosphere, with a rate

depending on temperature and humidity. It is recommended that the

material be dried in a dehumidifying dryer at 80 °C to 85 °C for 2-4

hours, prior to use.

Processing temperatures are recommended to be set at 190°C- 230 °C

for cylinder, and 40 °C to 80 °C for mold. SD-0150 ABS can be

processed under different conditions based on machinery available

and articles molded.

Reviews

There are no reviews yet.