LLDPE 209AA AKPC (MFI: 0.9)

Download TDS

Product Description:

“LL 0209AA” is a LLDPE copolymer with butene-1 as comonomer

which contains antioxidant.

It is recommended for general purpose applications.

It is suitable for blending with conventional LDPE.

Film made from pure LL 02090 AA has the following advantages

over conventional LDPE:

Better sealing,higher puncture resistance.

Greater drawdown capability.

Higher tensile strength.

Neutralizer: Calcium Stearate.

Antioxidant: Irganox1010, Irgafos168

Application:

Food Grade

Heave duty sacks, Agricultural films, liners.

Produce bags, Stretch film

LLDPE 209AA ARAK (MFI: 0.9)

Download TDS

Main application & Characteristics:

LL0209AA are linear low density polyethylene copolymers containing butene-1

.as a co-monomer

LL0209AA are suitable for general purpose films, neat or in lean blends with

LDPE and other ethylene polymers. Lean blends applications include sacks of all

. types, FFS and agricultural films

In lean blends they offer the following advantages:

− Greater draw down.

− Improved hot-tack and lower seal shrinkage.

− Better tear resistance.

− Higher tensile stress and elongation at break.

LL0209AA should be stored in the dry condition below the 50°C and avoided

. from the exposure of direct sunlight

. Recommended melt temperature for extrusion is about 180°C - 225°C

.LL0209AA are suitable for food contact

LLDPE 22B02 (MFI: 2)

Download TDS

Typical applications :

For use in lean and rich blend blown film application such as over wrap,

Counter bags, shrink film and boil in the bag applications

Artificial grass

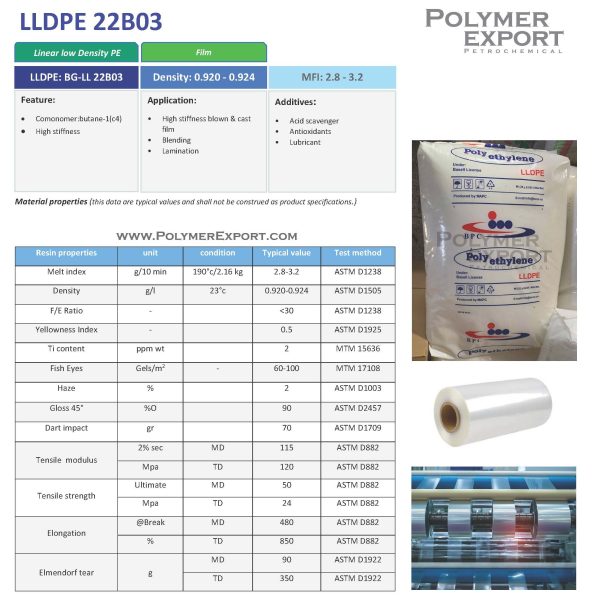

LLDPE 22B03 (MFI: 3)

Download TDS

Application:

• High stiffness blown & cast

film

• Blending

• Lamination

Feature:

Co monomer:butane-1(c4)

High stiffness

Additives:

• Acid scavenger

• Antioxidants

• Lubricant

LLDPE 235F6 (MFI: 0.6)

FOB BND: 1000_1020 $Mt

TDS PDF Download

Data sheet Vision

LLDPE 235F6 JPC JAM

Product Description:

LL-235F6 is a linear-low density polyethylene resin (LLDPE), obtained by gas

phase technology process. This grade designed for the production of different

type of films and agricultural tapes. In this grade excellent process ability,

mechanical properties, melt strength and draw ability achieved based on the

balanced molecular weight and molecular weight distribution. LL-235F6 has

good seal ability and approved for food contact applications

Application:

• Agricultural Films and Tapes

• Lamination

• Shrink Film

• Industrial Films, Frozen Food Packaging

Additives

•Thermal Antioxidant

(Process Stabilizer)

• Catalyst neutralizer

(acid scavenger, lubricant)