The generalized formula

for polyethylene glycol is: H(OCH2

CH2) n OH

N: Average number of repeating ethylene oxide groups.

There are many grades of PEGs that represents them by theirs

average molecular weight. For example, PEG 400 consists of a distribution of polymers of varying molecular weights with an

average of 400, which corresponds to an approximate

average number of repeating EO groups (n) of ≈9.

Polyethylene glycols are available in average molecular weight

ranging from 200 to 8000; this wide range of products provides

flexibility in choosing properties to meet the requirements of

many different applications.

Nomenclature of these products is different.

o CAS * name: ploy ethylene (oxyethylene) glycol.

* Chemical abstracts Society

o IUPAC*name: poly ethylene Glycol

* International Union of Pure & Applied Chemistry

o INCI * Name : PEG -4 , PEG-6 , PEG-8 ,

*International Nomenclature Cosmetic Ingredient

o CTFA name : PEG-4, PEG-6,PEG-8

* Cosmetics, Toiletry & Fragrance Association

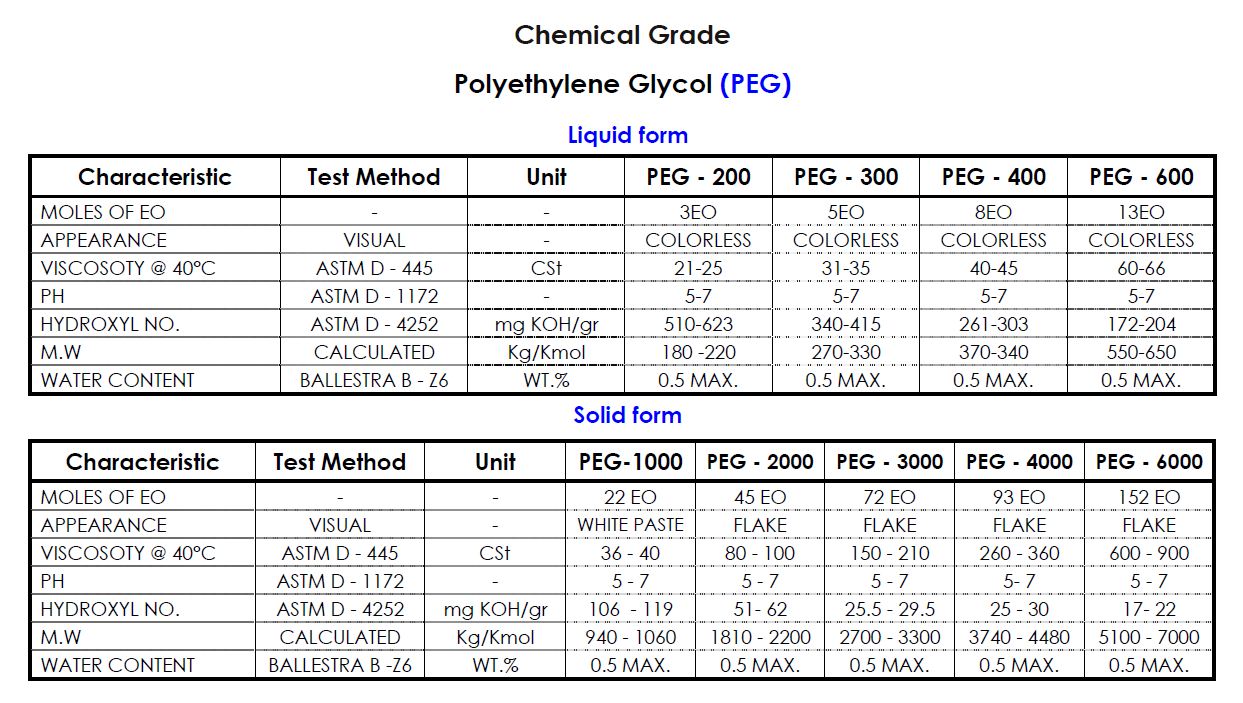

Depending on their average molecular weights, the Poly

ethylene glycols may be liquid or solid at STD condition.

PEG grades: 200,300,400,600 in liquid form , PEG 1000 ,1500 soft

solid (white) and PEG 2000,3000,4000,6000,8000 hard solid

(white).

The most important physical property:

Depend on molecular weight the wide range of the physical

property such as solubility , hygroscopic , vapour pressure , melting

or freezing point and viscosity are variable :

A: Solubility

Increasing the molecular weight of PEGs results in decreasing

solubility in water & solvents.

PEGs are also soluble in many polar organic solvents such as

acetone, alcohols.

B: Hygroscopic

PEGs are hygroscopic, it means that they attract and retain

moisture from the atmosphere.

Hygroscopic decrease as molecular weight increases.

C: viscosity

PEGs can be considered Newtonian fluids, so the kinematic

viscosity of PEGs decreases as temperature increases.

D: Stability

PEGs have low volatility and are thermally stable for limited period

of time below 300°c and without o 2

Applications:

• Pharmaceuticals:

PEG grades meet requirements of USP/ NF and BP and

are widely use in pharmaceutical formulations. As solvent,

water soluble, binder, lubricant, plasticizer and use in

ointment base, tablet coating, gelatine capsule, liquid

oral medications.

• Cosmetics:

As the water soluble , odourless , neutral, hygroscopic,

lubricant ,plasticizer, non-volatile , no irritating properties :

The PEGs are used in wide range of cosmetics and

personal care products such as creams , lotions , sticks ,

cakes , powders , jellies.

• Household products:

Soaps, detergents, polishes & cleaners are main

applicant of poly ethylene glycols, because these

products are water soluble & inert, with low volatility and

low toxicity.

• Ceramics and tile:

As the plasticizer, lubricity, binders and carriers properties:

PEGs are widely use in ceramic and tile industry.

• Adhesives and textile:

As the plasticizer, lubricants, softeners, antistatic agents &

conditional agents, PEGs are used in adhesives & textile

industry.• Other applications:

– Agriculture as water solubility & solubilize for organic insecticides.

– paper , printing and inks as softener, humectants , solvents ,

lubricants & carriers

– Paints & coating as intermediates for alkyd & polyester resins.

• Handling and storage:

PEGs product are only slightly toxic & safe for use in domestic

cleaning products , when handling products, recommended that

use safety goggles, PVC gloves & apron.

In contact: with eye wash with running water for 15 minutes.

With skin wash area with water.

Injection: seek medical.

The PEGs product should be stored in dry, covered area and far

away from sources of heat & ignition.• Packaging & shelf life:

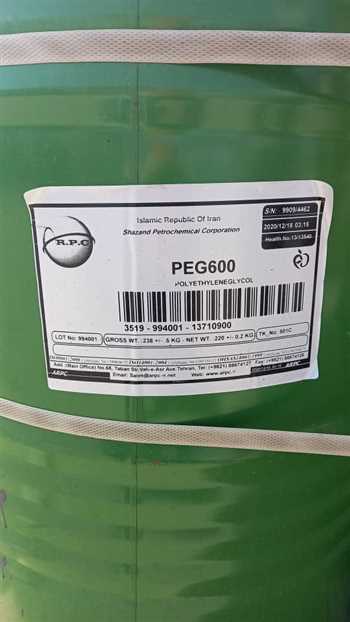

Liquid form of PEG (200 to 1000) are packed in 220 lit (net: 200 Kg)

drums, each 4 drum stepped of a pallet.

Solid form( up to PEG 1000) packed in Bag ( net : 25 Kg)

The PEG products have shelf life of 24 months from the date of

manufacture & maintained in adequate storage condition.

Shelf life of pharmacy grades is 12 months.

Reviews

There are no reviews yet.